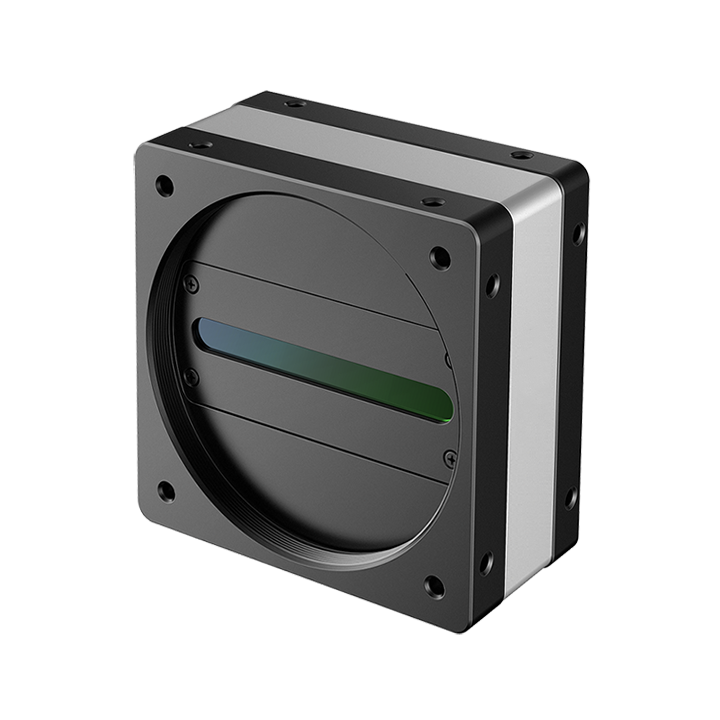

Hifly Vision 10 Gige 8K Line Scan produk baru, kegemaran jurutera.

Cari kamera imbasan garis 8K hifly 10 giga yang baru, direka untuk aplikasi pengimejan berkelajuan tinggi, menjadikannya kegemaran di kalangan jurutera dalam bidang penglihatan mesin.

lihat lebih banyak