Важность подсветки в визуальной системе и анализ ее применения

Введение в подсветку в визуальных системах

Подсветка в визуальных системах является значительным достижением в технологии отображения, играя ключевую роль в улучшении четкости и детализации визуальных презентаций. Подсветки работают, размещая источник света за дисплеем, чтобы увеличить яркость, что, в свою очередь, улучшает видимость изображений и текста. Это особенно важно в условиях с изменяющимся освещением, обеспечивая, чтобы дисплеи оставались читаемыми и привлекательными независимо от внешних факторов.

Функция подсветки охватывает различные приложения, где повышенная видимость имеет первостепенное значение. Например, на торговых выставках или в розничной торговле подсвеченные дисплеи помогают брендам привлекать внимание, делая графику более яркой и привлекательной. Подсветка выделяет тонкие детали и обеспечивает ясность сообщения, тем самым способствуя эффективной коммуникации и вовлечению аудитории. Эта технология незаменимо используется в различных секторах, где поддержание высокой видимости визуальных материалов имеет решающее значение для операционного успеха.

Типы технологий подсветки

Технология LED-подсветки стала доминирующим выбором в системах отображения благодаря своей энергоэффективности и впечатляющим уровням яркости. Согласно отраслевым источникам, LED-дисплеи могут достигать экономии энергии до 30% по сравнению с традиционными технологиями освещения. Это делает светодиоды не только экономически выгодными, но и экологически чистыми, так как они требуют меньше энергии для работы, обеспечивая при этом яркое и стабильное освещение. Переход на LED-подсветку стал широко распространенным, оказав значительное влияние на снижение углеродного следа цифровых дисплеев.

Понимание различий между дисплеями с боковой подсветкой и прямой подсветкой имеет решающее значение для выбора правильной технологии подсветки. Дисплеи с боковой подсветкой имеют светодиоды, выровненные вдоль краев экрана, направляя свет к центру. Эта конфигурация идеальна для создания ультратонких дисплеев, которые эстетически привлекательны и потребляют меньше материала. Напротив, дисплеи с прямой подсветкой имеют светодиоды, равномерно распределенные за экраном, предлагая лучшую равномерность света и более высокую яркость. Этот тип подходит для сред, где четкость изображения и детали имеют первостепенное значение, например, в экранах высокой четкости и профессиональных мониторах.

Технологии подсветки имеют решающее значение в различных отраслях, обслуживая множество приложений. В потребительской электронике такие продукты, как телевизоры и компьютерные мониторы, в значительной степени полагаются на LED-подсветку для улучшения качества изображения, предлагая четкие и ясные визуальные эффекты. В рекламе подсвеченные вывески играют важную роль, используя яркие дисплеи, которые привлекают внимание в многолюдных местах или на открытом воздухе. Кроме того, автомобильные дисплеи выигрывают от технологий подсветки, предоставляя водителям четкие и читаемые приборные панели и интерфейсы даже в условиях низкой освещенности. Каждое приложение использует специфические преимущества технологий подсветки для удовлетворения своих уникальных требований.

Применения подсветки в визуальных системах

Подсветка играет решающую роль на торговых выставках и выставках, привлекая внимание к продуктам и создавая увлекательные, погружающие среды. Выставляющие компании часто используют подсветку, чтобы выделить ключевые особенности своих экспозиций, делая их заметными среди толпы. Яркие, освещенные графики, запечатленные с помощью подсветки, обеспечивают, чтобы бренды не только видели, но и запоминали. Для компаний, стремящихся привлечь участников и эффективно донести свои сообщения, включение подсвеченных экспозиций на таких мероприятиях является необходимым.

Розничные витрины также значительно выигрывают от эффективной подсветки, которая может влиять на решения потребителей о покупке. Улучшая видимость продукта, ритейлеры могут направлять внимание клиентов на определенные товары или рекламные зоны, увеличивая потенциал продаж. Освещенные витрины могут преобразовать обычные оконные установки или внутренние акции в визуально захватывающие впечатления. Исследования показали, что клиенты с большей вероятностью взаимодействуют с продуктами, которые хорошо освещены благодаря подсветке, что приводит к увеличению потока клиентов и продаж в розничной торговле.

В области машинного зрения постоянная подсветка необходима для точной визуальной инспекции и контроля качества. Обеспечивая равномерные условия освещения, системы с подсветкой помогают устранить тени и выделить дефекты в производственных процессах. Согласно недавним исследованиям в области производства, подсветка улучшает точность инспекции до 15%, что имеет решающее значение для поддержания высоких стандартов качества и снижения уровня дефектов. Эта технология необходима для задач, требующих точности, таких как инспекция электроники, где обнаружение мелких неисправностей может предотвратить дорогостоящие ошибки.

Проблемы внедрения систем подсветки

Реализация систем подсветки часто сталкивается с проблемами из-за факторов окружающей среды, таких как температура и влажность. Исследования показывают, что экстремальные температуры могут привести к тепловым колебаниям, вызывая расширение или сжатие материалов, и это колебание может повлиять на целостность подсветки. Высокий уровень влажности может привести к накоплению влаги, что может вызвать электрические неисправности или ухудшить отражающую способность подсвечиваемых поверхностей. Обеспечение эффективного контроля температуры и вентиляции, а также использование влагостойких материалов может смягчить эти воздействия окружающей среды.

В дополнение к экологическим проблемам, общими вопросами в технологии подсветки являются цветовая однородность и потребление энергии. Цветовая однородность имеет решающее значение для стабильного качества изображения. Вариации могут возникать из-за неравномерного распределения света или старения источников света, что может серьезно повлиять на производительность, особенно в точных условиях, таких как машинное зрение. Исследования показывают, что интеграция современных светодиодов и использование систем калибровки могут значительно улучшить стабильность цвета. Еще одной серьезной проблемой является потребление энергии, так как высокое энергопотребление может привести к увеличению затрат и образованию тепла. Чтобы решить эту проблему, эксперты рекомендуют использовать энергоэффективные решения для освещения и системы, разработанные для оптимизации потребления энергии, обеспечивая баланс между производительностью и эффективностью потребления.

Выбор правильной подсветки для ваших нужд

При выборе правильной подсветки важно учитывать компоненты, которые бесшовно интегрируются с вашей системой зрения для оптимальной производительности.

Одним из таких компонентов является Стандартный цифровой контроллер DCS-2C003W-5PS Этот контроллер разработан с гибкостью, чтобы соответствовать различным приложениям благодаря своей цифровой и стандартной работе с постоянным током. Он поддерживает два канала с выходом 5В и может обрабатывать выходную мощность 3Вт на канал, что делает его идеальным для индивидуальных решений освещения в различных инспекционных средах.

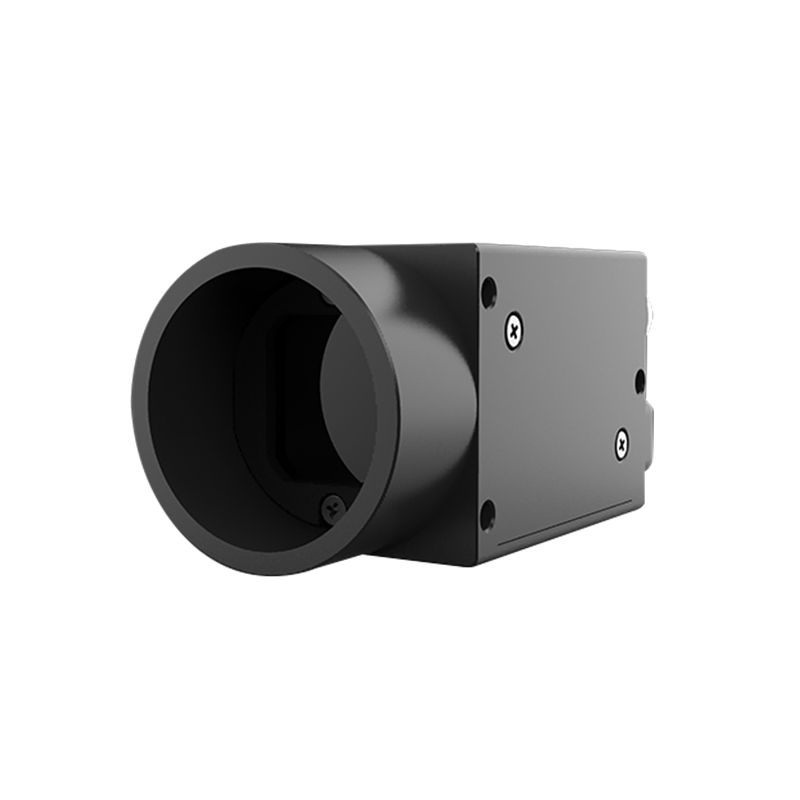

Этот Камера для сканирования площади MV-AU2000RC/M Превосходит в обеспечении высококачественной съемки при интеграции систем подсветки. С его значительным 20МП CMOS сенсором с роллинг-шаттером он обеспечивает превосходное разрешение изображения 5488×3672 пикселей. Эта возможность гарантирует яркое захватывание деталей, что необходимо для приложений, требующих точности, таких как инспекции компонентов или идентификация высокодетализированных узоров.

Этот Камера для сканирования области MV-AU1000RC/M предлагает заметные конкурентные преимущества, особенно в контекстах, требующих высокой точности и цветопередачи. С 10-мегапиксельным CMOS-датчиком с глобальным затвором она захватывает изображения с разрешением 3664×2748 пикселей. Эта камера хорошо подходит для приложений, которые выигрывают от детализированной съемки в сочетании с подсветкой, таких как инспекция в фармацевтике или электронике, где ясность и детали имеют критическое значение.

Важно оценить эти варианты на основе ваших конкретных требований к приложению, чтобы обеспечить максимальную эффективность и точность в вашей системе машинного зрения.

Уход и обслуживание для дисплеев с подсветкой

Обеспечение долговечности и оптимальной работы подсвечиваемых дисплеев требует постоянных практик обслуживания, основанных на отраслевых стандартах. Регулярно очищайте дисплеи с помощью мягкой, безворсовой ткани, чтобы удалить пыль и пятна, избегая резких химикатов, которые могут повредить поверхность. Проводите периодические проверки световых компонентов, чтобы своевременно устранять любые неисправные светодиоды, обеспечивая яркость и эффективность дисплея. Кроме того, всегда следуйте инструкциям производителя по обслуживанию, чтобы избежать аннулирования любых гарантий.

В дополнение к регулярному обслуживанию, правильное хранение является ключом к сохранению как функциональности, так и внешнего вида устройств с подсветкой. Храните дисплеи в прохладной, сухой среде, вдали от прямых солнечных лучей и экстремальных температур, которые могут повредить материалы. Используйте защитные чехлы или кейсы во время хранения и транспортировки, чтобы предотвратить царапины и повреждения от ударов. Эти меры обеспечивают сохранение дисплеев с подсветкой в безупречном состоянии, готовыми привлечь внимание в любое время. Соблюдая эти рекомендации, вы можете максимизировать свои инвестиции и продлить срок службы ваших активов с подсветкой.

Заключение: Будущее подсветки в визуальных системах

Технологии подсветки имеют глубокое значение в современных визуальных системах, повышая четкость и эффективность в различных приложениях. От потребительской электроники до сложных промышленных систем, эволюция технологий подсветки постоянно способствовала улучшению видимости и точности. Эти достижения имеют решающее значение не только для оптимизации производительности, но и для установления нового стандарта качества в визуальном представлении.

Заглядывая в будущее, мы можем ожидать захватывающих достижений в области подсветки, особенно благодаря потенциальной интеграции с умными технологиями. Поскольку энергоэффективность становится первоочередной задачей, ожидается, что системы подсветки станут более устойчивыми, уменьшая свое воздействие на окружающую среду. Более того, такие инновации, как адаптивное освещение, которое реагирует на окружающие условия и потребности пользователя, проложат путь к более персонализированным и эффективным визуальным впечатлениям. Будущее подсветки обещает стимулировать дальнейшие инновации, обеспечивая устойчивый прогресс в области визуальных технологий.