Do You Know Distortion in Machine Vision?

Have you ever encountered a distorted image? An object that should have been straight becomes curved, even the edges are curved. This is actually caused by lens distortion, which causes the image of the object to be distorted, but it has no effect on clarity.

There are two main types of optical distortion in machine vision systems: radial distortion and tangential distortion. Understanding their causes, effects, and correction methods is critical to ensuring reliable visual inspection results.

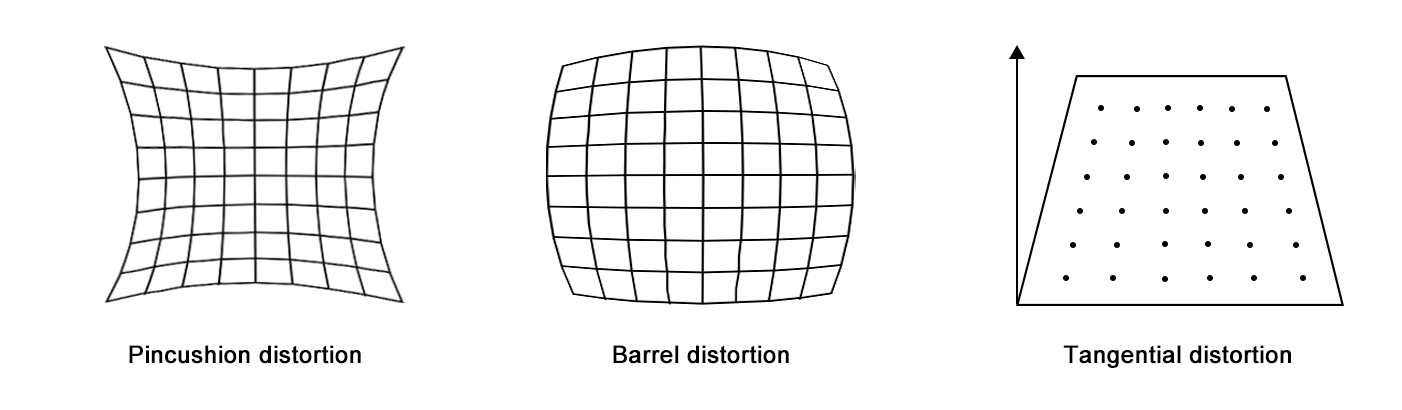

1. Radial Distortion and Tangential Distortion

Among them, the distortion caused by the lens not being parallel to the imaging surface due to assembly errors is called tangential distortion, which will cause the center and edge of the image to be distorted, and the horizontal or vertical lines of the image will become curved. The radial distortion is caused by the shape and process of the lens. The closer to the edge of the lens, the more serious the distortion. Generally, the convex radial distortion is called barrel distortion, and the concave one is called pincushion distortion.

2. The Imperative of Distortion Correction

In precision-dependent applications like industrial metrology or automated quality control, uncorrected distortions can lead to catastrophic measurement errors. A deviation of even a few pixels might translate to significant dimensional inaccuracies in real-world units. Consequently, distortion correction becomes indispensable for image-based decision-making systems.

3. Hybrid Correction Strategies

Since distortion is an inherent characteristic of optical systems, complete elimination remains unattainable. However, a combination of hardware adjustments and computational methods can mitigate its impact:

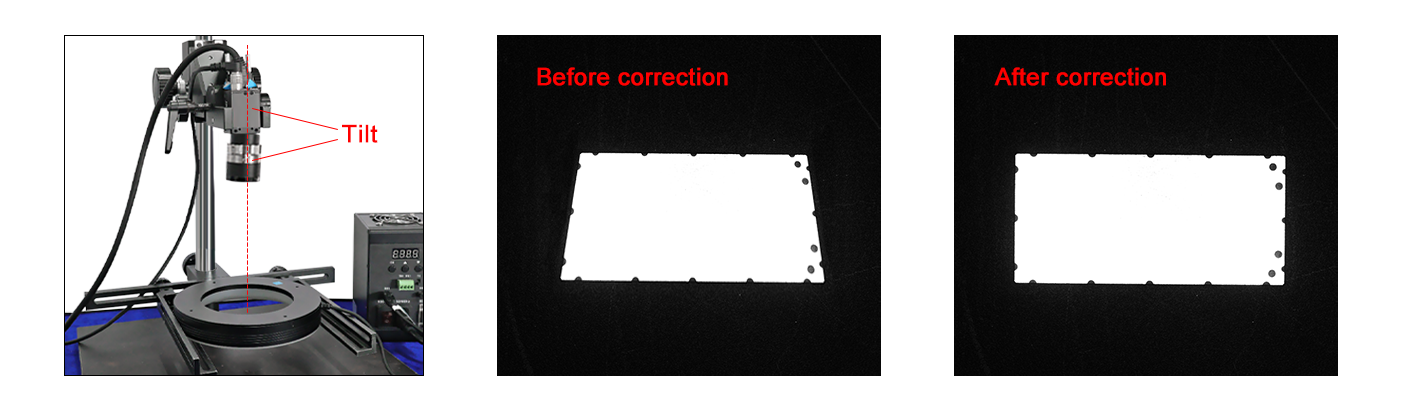

Hardware Solutions for Tangential Distortion

Addressing tangential distortion primarily involves mechanical recalibration. By repositioning the lens to achieve perfect parallelism with the sensor.

Software Solutions for Radial Distortion

Radial distortion is usually corrected through software. The distortion coefficient of the lens is calculated and then processed by software.

Through camera calibration (e.g., using checkerboard patterns), these parameters are computed and applied to remap distorted pixels to their theoretical positions.

Conclusion: Balancing Optics and Computation

While lens distortions pose persistent challenges in machine vision, their effects can be systematically managed. Tangential distortion demands meticulous hardware alignment, whereas radial distortion necessitates sophisticated software correction. By integrating both approaches, engineers can restore geometric fidelity to images, ensuring that vision systems deliver the accuracy required in modern industrial applications.