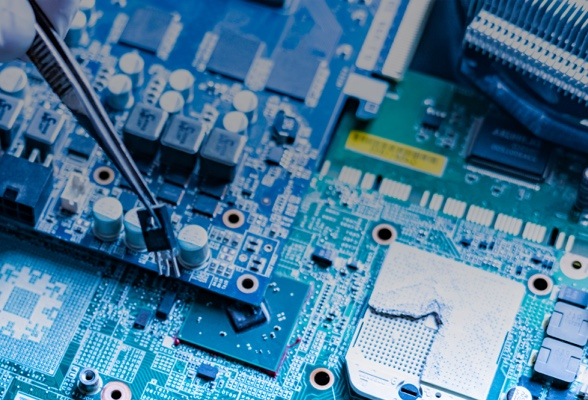

As the largest field of machine vision application in China, 3C electronics can see the figure of machine vision in all links of the electronic manufacturing industry chain, as small as imaging modules, USB connectors, and as large as mobile phone frames, PC motherboards and other devices. It includes application scenarios such as processing and assembly of connectors, screen alignment and fitting, and flat plate scratch detection.

In the pre-middle process of semiconductor manufacturing, machine vision is mainly used in precision positioning and detection, and the post-process mainly involves the electrical detection, cutting, packaging, and detection of wafers. Machine vision helps the semiconductor industry to upgrade equipment, improve the process level of the production line, and improve the quality and yield of products, which is one of the core technologies of modern industry.

In the context of global "carbon neutrality" and "carbon peak", the intelligent manufacturing industry of photovoltaic, lithium and other industries has been upgraded. Among them, machine vision has a very wide range of applications in the entire process segment of photovoltaic and lithium batteries, including code reading traceability, bad removal of raw materials, assembly guidance and other application scenarios.

The manufacturing process of the automobile industry has achieved a high degree of automation, ensuring the efficiency and safety of the production process is the primary goal of automobile manufacturers. Machine vision products can effectively improve the reliability of products at all stages of the automotive manufacturing and assembly process to meet the stringent quality requirements of the automotive industry.

With lean operations and weak margins, the food and drug industry is facing unprecedented pressure and challenges to optimize the overall efficiency of equipment without sacrificing quality. Introduce machine vision and code reading solutions to minimize downtime, ensure that safe, quality products are always available and can be easily tracked throughout the supply chain.

The emergence of machine vision effectively solves the problems of single traditional logistics means, high reading error rate, large fluctuation of bubble metering efficiency and rising labor costs. A series of visual solutions such as automatic grasp, code reading, volume measurement, sheet tracking, etc., are becoming an indispensable intelligent means in the logistics industry.