How To Choose The Pixel For Industrial Cameras?

There are so many industrial cameras with various pixel on the market. What does “pixel” actually represent, and how do we select the right pixel for an industrial camera? This article will break it down through three key aspects.

- Pixel Definition

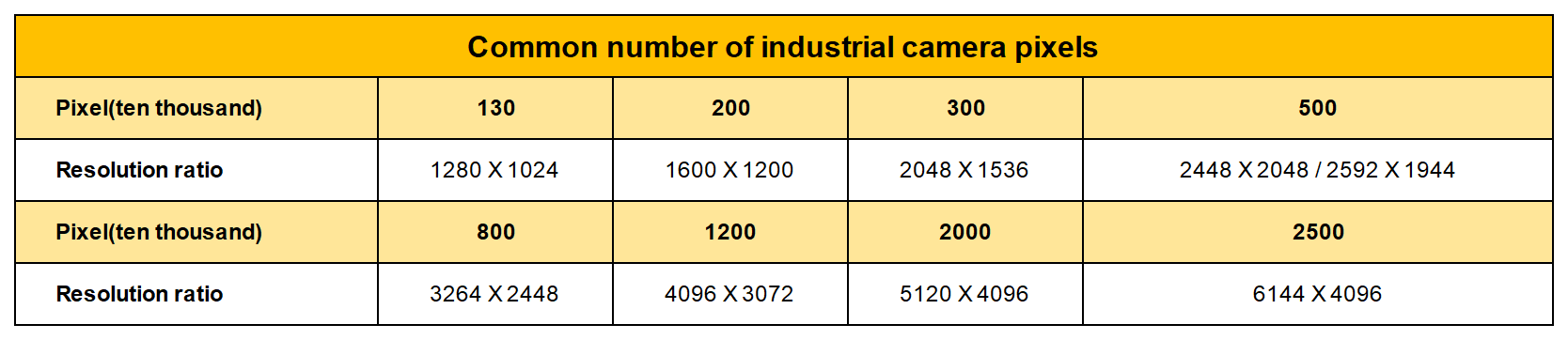

First, let’s understand what a pixel is. The pixel of an industrial camera reflects the resolution of its image sensor, typically expressed in tens of thousands, megapixels, or even tens of megapixels. A pixel is the smallest visible unit in an image—discrete points on the sensor that capture light. Thus, the number of pixels determines the level of detail and clarity the camera can capture. More pixels mean higher resolution, resulting in sharper, more detailed images.

- Pixel Calculation

How do we interpret a camera’s pixel count? It’s simple.

For example, a camera with a resolution of 1280 × 1024 has a total pixel count of ~1.3 million (1280 × 1024 ≈ 1,310,000). This means images from this camera are composed of 1.3 million pixels. Pretty straightforward, right?

- Practical Application

How do we choose the right pixel count for real-world scenarios?

Suppose you need a pixel accuracy of 0.1 mm for an object measuring 50 mm × 40 mm. The required resolution would be calculated by dividing each dimension by 0.1 mm :

Length: 50 mm ÷ 0.1 mm = 500 pixels

Width: 40 mm ÷ 0.1 mm = 400 pixels

A camera with a 500 × 400 resolution (total ~200,000–300,000 pixels) would suffice here.

By aligning pixel count with your specific application needs and budget, you can select the ideal industrial camera.