Vad är en områdesskanningskamera? Arbetsprincip och analys av tillämpningsscenarier

Förståelse av Area Scan Kamera Teknik

Area scan-kameror fungerar som den mångsidiga bildlösningen inom maskinsyn, och använder en matris av pixlar för att fånga omfattande bilder av scener, objekt eller händelser. Dessa kameror skiljer sig avsevärt från linjescankameror, som är utrustade med en enda rad av pixlar för att snabbt samla in data när ett objekt rör sig. Skillnaden ligger i deras tillämpningar—medan area scan-kameror är idealiska för stabila bildsituationer, är linjescankameror anpassade för kontinuerlig objektinspektion i höga hastigheter.

De kritiska komponenterna i en områdesskanningskamera inkluderar sensorer, optik och bildbehandlingsenheter. Sensorn, som består av pixlar, fångar ljus för att producera en bild. Optiken, som består av linser, bestämmer kamerans synfält och den övergripande bildkvaliteten. Slutligen omvandlar bildbehandlingsenheterna rådata till användbara digitala bilder, ofta med hantering av brusreducering och förbättring av utdataupplösning. Historiskt sett har områdesskanningskameror utvecklats från skrymmande, lågupplösta enheter till mer sofistikerade, kompakta system med kapabiliteter som infraröd känslighet, vilket därmed utökar deras tillämpningar inom maskinsyn genom årtionden av innovation. Denna evolution belyser deras anpassningsförmåga och ökade värde i moderna industriella och kommersiella scenarier.

Nyckelfunktioner och fördelar med områdesskanningskameror

Områdesskanningskameror är kända för sina imponerande högupplösta bildbehandlingsförmågor, vilket ger fantastisk bildklarhet. Utrustade med avancerade bildsensorer erbjuder dessa kameror upplösningar som kan nå upp till 604 megapixlar, vilket säkerställer precisa och skarpa bilder som är avgörande för detaljerade inspektioner. Detta höga pixeltal förbättrar avsevärt kvaliteten på de fångade bilderna, vilket gör dessa kameror ovärderliga i miljöer som kräver detaljerad visuell data.

Mångsidigheten hos områdesskanningskameror sträcker sig över olika industrier, vilket gör dem oumbärliga verktyg inom områden som elektronik, livsmedelsförpackning och textiltillverkning. Inom elektronik underlättar de detaljerade inspektioner av kretskort och komponenter; inom livsmedelsförpackning säkerställer de kvalitetskontroll genom att upptäcka defekter; medan de inom textil hjälper till med felupptäckning. Denna flexibilitet understryker deras betydelse i olika operativa miljöer.

Områdesskanningskameror utmärker sig i att tillhandahålla realtidsbilder, vilket avsevärt förbättrar övervaknings- och inspektionsprocesser. Denna realtidskapacitet leder till snabb upptäckte av defekter och omedelbara korrigerande åtgärder, vilket förbättrar produktiviteten och minskar stillestånd. Den omedelbara bearbetningen och analysen av bilder strömlinjeformar också arbetsflöden och stödjer effektiva kvalitetskontrollprotokoll.

Förutom sin prestanda värderas områdesskanningskameror för sin energieffektivitet och kostnadseffektivitet. Dessa kameror är utformade för att konsumera mindre energi, vilket minskar driftskostnaderna samtidigt som de upprätthåller hög prestanda. Deras kostnadseffektivitet, i kombination med låga underhållskrav, bidrar till deras utbredda användning inom både stora och små industrier, vilket säkerställer en hög avkastning på investeringar.

Jämförande analys: Områdesskanningskameror vs. Linjeskanningskameror

Att förstå skillnaderna mellan områdesskanningskameror och linjeskanningskameror är avgörande för att välja den ideala bildlösningen. Områdesskanningskameror fångar en fullständig bild i en enda bildruta tack vare sin matris av pixlar, vilket gör dem lämpliga för applikationer som kräver enkel installation och justering. I kontrast använder linjeskanningskameror en enda rad av pixlar, samlar data rad för rad och är optimala för att fånga hög hastighet rörliga objekt på ett transportband eller produktionslinje.

Olika scenarier belyser den optimala användningen av varje kameratyp. Områdesskanningskameror är idealiska för applikationer där högupplösta bilder är nödvändiga för statiska eller långsamt rörliga objekt, såsom vid inspektion av elektronik eller kvalitetskontroll inom tillverkning. Samtidigt utmärker sig linjeskanningskameror i kontinuerliga processer som webbinspektion för papper eller textilier, där objekt rör sig snabbt.

Experter betonar ofta avvägningarna mellan dessa system. Områdesskanningskameror hyllas för sin enkelhet och användarvänlighet, medan linjeskanningskameror noteras för sin effektivitet i hög hastighet. Fallstudier, såsom avbildning av cylindriska delar med en linjeskanningskamera, förstärker dessa observationer och visar hur varje kameratyp effektivt kan uppfylla specifika industriella behov.

Vanliga användningsområden för områdesskanningskameror

Områdesskanningskameror är avgörande inom industriell automation och strömlinjeformar betydligt processer på tillverkningslinjer. Dessa kameror ger högkvalitativa bilder för uppgifter som att styra robotarmar, sortera föremål och övervaka produktion. Till exempel kan områdesskanningskameror fånga detaljerade bilder av produkter som rör sig på ett transportband, vilket möjliggör realtidsjusteringar och minskar mänsklig intervention. Denna teknik ökar inte bara effektiviteten utan säkerställer också precision och konsekvens i verksamheten.

Inom medicinsk avbildning spelar områdesskanningskameror en avgörande roll genom att erbjuda högupplösta bilder som är avgörande för diagnostisk noggrannhet. Tekniker som MRI och CT-skanningar använder ofta dessa kameror för att tillhandahålla detaljerad visuell data, vilket hjälper vårdpersonal att fatta informerade beslut. Sådana tillämpningar kräver kameror som kan hantera strikta specifikationer och leverera konsekvent högpresterande avbildning. Därför föredras områdesskanningskameror ofta på grund av deras överlägsna bildkvalitet och tillförlitlighet i kritiska medicinska scenarier.

Kvalitetsinspektion inom tillverkning drar stor nytta av användningen av områdesskanningskameror. Dessa kameror förbättrar noggrannheten under inspektionsprocessen, identifierar defekter med precision och säkerställer att produkter uppfyller strikta kvalitetsstandarder. Denna förbättring minskar avfallet avsevärt genom att eliminera defekta föremål innan de går vidare längs produktionslinjen. Enligt senaste statistik kan implementering av områdesskanningskameror i tillverkningsinspektionsprocesser leda till effektivitetsförbättringar på upp till 15%, vilket framhäver deras roll i att stödja hållbara metoder.

Utvalda produkter med områdesskanningskameror

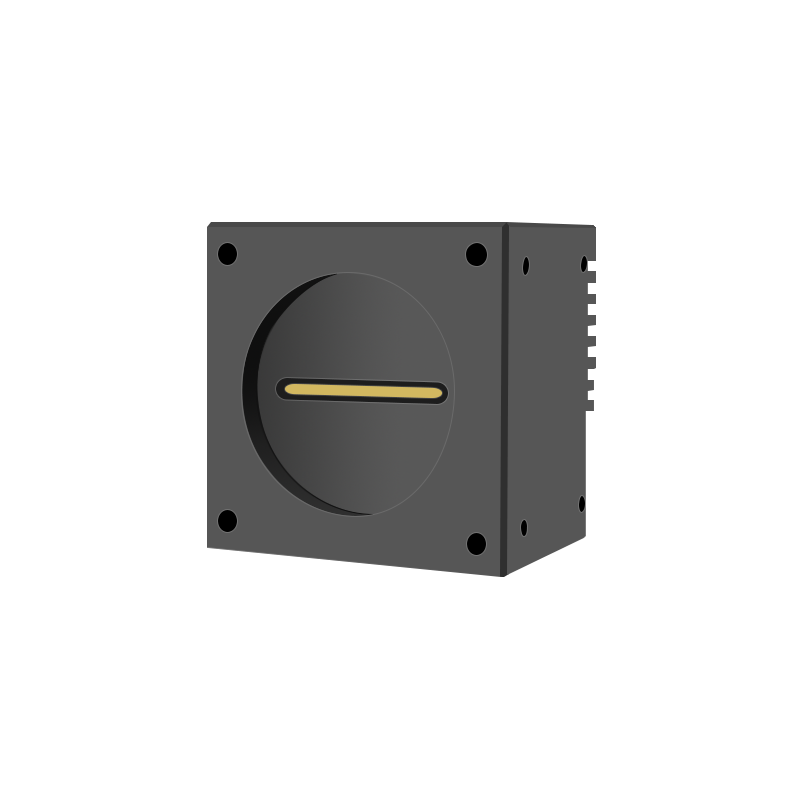

Den MV-L044M-GE Line Scan-kamera är en framstående produkt inom industribildbehandling. Känd för sin höga upplösning och robusta funktioner, erbjuder den en rad tillämpningar, inklusive maskinsynssystem och ytkontroll. Med specifikationer som 4096×8 upplösning och en global slutare, är den perfekt för hög hastighet bildbehandling. Denna kameras mångsidiga kompatibilitet med GigE säkerställer sömlös integration i befintliga system, vilket gör den till ett föredraget val för många sektorer.

Den HF-130H-M/C svetsövervakningskamera står ut i svetsapplikationer på grund av sin robusta prestanda och anpassningsförmåga. Den är byggd för att klara av krävande miljöer och fångar varje detalj med sin 1,3MP upplösning och CMOS-sensor. Denna kameras förmåga att leverera klara bilder vid 60fps, tillsammans med ett mångsidigt arbetsavstånd, gör den oumbärlig för att säkerställa svetskvalitet och säkerhet.

Specialiserade bildbehandlingsuppgifter drar stor nytta av HF-W1250412X svetslins . Denna lins förbättrar bilder med sitt precisa förstoringsområde och överlägsen DOF, vilket stödjer intensiva inspektionsprocesser. Dess designkapacitet för hög MTF säkerställer skarp bildkvalitet, vilket är avgörande för att identifiera svetsdefekter och intrikata detaljer i olika industriella tillämpningar.

Verkliga tillämpningar av dessa produkter har konsekvent visat deras effektivitet i att förbättra precision och öka operationell effektivitet. Från att förbättra svetskvalitet till att erbjuda oöverträffade avbildningslösningar, är dessa verktyg integrerade i banbrytande tillverknings- och inspektionsprocesser.

Slutsats: Framtiden för områdesskanningskameror

Framtiden för områdesskanningskameror formas av olika framväxande trender inom maskinsyn, särskilt med innovationer inom områdesskanningsteknik. En betydande utveckling är integrationen av AI och maskininlärning, vilket förväntas förbättra dessa kameras kapabiliteter i komplexa inspektions- och automatiseringsprocesser. AI kommer ytterligare att möjliggöra för områdesskanningskameror att utföra komplexa uppgifter, såsom realtidsbildanalys och smart beslutsfattande, som tidigare var otänkbara.

Automatisering, i kombination med AI-teknologier, kommer att spela en avgörande roll i utvecklingen av områdesskanningskameror. Dessa framsteg kommer att möjliggöra sömlös integration i smarta tillverkningsmiljöer, där precision och hastighet är avgörande. Som ett resultat kommer företag sannolikt att uppleva ökad produktivitet och minskade driftskostnader, vilket driver ytterligare adoption över olika industriella sektorer.

Framöver är marknaden för områdesskanningskameror redo för betydande tillväxt. Med en förväntad ökning av efterfrågan, drivet av kontinuerliga teknologiska framsteg, förväntas dessa kameror omvandla industrier genom att förbättra kvalitetskontroll, öka säkerhetsåtgärder och möjliggöra avancerad dataanalys. Denna tillväxtbana presenterar en spännande möjlighet för företag att utnyttja framväxande teknologier och ligga steget före i en snabbt utvecklande marknad.