What Is Fly-Scanning in Industrial Cameras? Your Guide to High-Speed Precision

Imagine a camera that captures flawless images of objects zooming by at breakneck speed—without missing a single detail. That’s the magic of *fly-scanning* in industrial cameras, a game-changing technique revolutionizing automation. From inspecting endless rolls of steel to spotting defects in high-speed packaging, fly-scanning delivers precision where it matters most. But what exactly is it, and how does it work?

In this post, we’ll demystify fly-scanning, explore its role in industrial vision, and show why it’s a must-have for modern production lines. Whether you’re new to machine vision or looking to optimize your setup, this guide will bring the concept into sharp focus. Let’s dive in and see fly-scanning in action!

Understanding Fly-Scanning: The Basics

Fly-scanning, often called “on-the-fly” scanning, is a method used by industrial cameras—typically line-scan cameras—to capture images of objects in continuous motion. Unlike traditional cameras that need a pause to snap a full frame, fly-scanning grabs data line by line as the object moves past the lens. Think of it like reading a book one line at a time, but so fast it feels instant.

This technique is built for speed and efficiency, making it ideal for industries where downtime isn’t an option. It’s the backbone of high-throughput applications, ensuring every inch of a moving surface is inspected without slowing the line.

How Fly-Scanning Works

Fly-scanning sounds futuristic, but its mechanics are elegantly simple. Here’s the breakdown:

1. Motion Sets the Stage

The object—say, a sheet of paper or a conveyor of bottles—moves steadily across the camera’s view, usually on a production line.

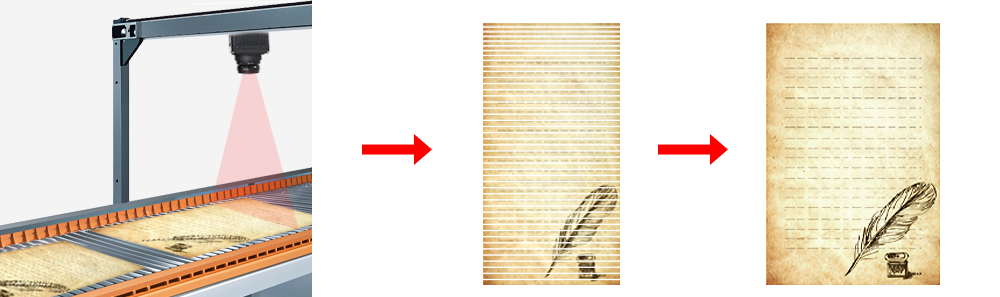

2. Line-by-Line Capture

A line-scan camera, equipped with a single row of sensors, snaps a thin slice of the scene with each pass. These “lines” are captured thousands of times per second, triggered by precise timing or an encoder synced to the object’s speed.

3. Building the Image

Specialized software stitches these lines together into a continuous, high-resolution image. The result? A crystal-clear picture of the entire object, no matter how fast it’s moving.

It’s like assembling a puzzle in real time, with each piece perfectly aligned to reveal the full story—defects, patterns, or all.

Why Fly-Scanning Matters

Fly-scanning isn’t just a tech trick; it’s a necessity for industries chasing efficiency. Here’s why it’s a big deal:

Speed Without Sacrifice: It keeps up with the fastest production lines, capturing details at rates that traditional cameras can’t match.

No Stops Needed: Unlike area-scan cameras that require objects to pause, fly-scanning thrives on motion, eliminating bottlenecks.

Scalable Precision: Whether inspecting a tiny circuit or a massive roll of fabric, it delivers consistent, high-quality images.

Real-World Applications

Fly-scanning shines in scenarios where speed and scale collide. Here are some prime examples:

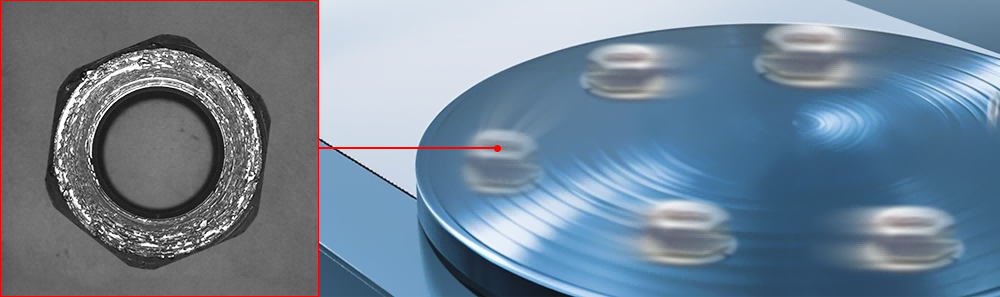

Manufacturing: Checking for scratches or dents on metal sheets as they race through production.

Printing: Ensuring ink alignment on high-speed presses, catching errors before they stack up.

Food Processing: Scanning conveyor belts to spot mislabeled cans or damaged packages.

Textiles: Inspecting endless rolls of fabric for tears or weave flaws without slowing the loom.

In each case, fly-scanning turns chaotic motion into actionable data, keeping quality sky-high.

Fly-Scanning vs. Traditional Methods

To appreciate fly-scanning, let’s compare it to area-scan cameras (the kind in your phone). Area-scan cameras capture full frames, great for static objects but tricky for fast-moving ones. They often need strobe lights or pauses to avoid blur, which can clog up a production line.

Fly-scanning, paired with line-scan cameras, flips the script. It’s built for motion, grabbing razor-sharp images without ever asking the line to slow down. The trade-off? It requires precise synchronization and specialized software, but the payoff in speed and efficiency is worth it for high-volume tasks.

Key Benefits of Fly-Scanning

High Throughput: Perfect for inspecting long or continuous objects like pipes or webs.

Superior Resolution: Line-by-line capture allows ultra-dense pixel arrays, catching details area cameras might miss.

Compact Data: Generates leaner image streams, easing the load on processing systems.

Versatility: Works across industries, from semiconductors to food packaging.

Things to Consider

Thinking about fly-scanning for your setup? Keep these in mind:

Motion Control: Your conveyor or object needs consistent speed for seamless imaging.

Lighting: Bright, focused light (like line LEDs) enhances clarity, as fly-scanning loves good illumination.

Software: You’ll need robust vision software to handle the rapid data flow and stitch images correctly.

Cost: Line-scan systems can have higher upfront costs than area-scan setups, but their efficiency often saves money long-term.

Why Fly-Scanning Is the Future

In a world where every second counts, fly-scanning is more than a tool—it’s a competitive edge. It lets industries push the limits of speed without compromising quality, turning high-pressure production into a smooth, reliable process. For businesses aiming to scale up or streamline, it’s a no-brainer.

Ready to Capture the Future?

Fly-scanning could be the key to unlocking your production line’s full potential. Want to see it in action? Explore our cutting-edge line-scan camera solutions or connect with our machine vision experts for a tailored demo. Don’t let defects slip through the cracks—contact HIFLY today and start scanning smarter!