The surface of automobile air conditioning radiator is defective due to the process, handling and other reasons, and the use of manual detection is inefficient and easy to misjudge. Deep learning is now used to replace the manual.

Share

1). Project background:

Requirement description:

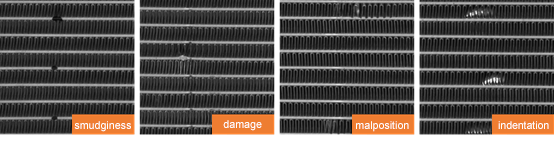

1. the air conditioner will have defects after the completion of production and handling, and it is necessary to detect defects such as dirt, damage, dislocation, and indentation.

2. Change the status quo of low efficiency and low accuracy of manual detection.

Technical requirements:

1. Different defect categories are required to be detected and classified.

2. the detection rate is required to be above 99.95%, and the false detection rate is controlled below 1%.

3. compatible with different product types.

2). Solution architecture:

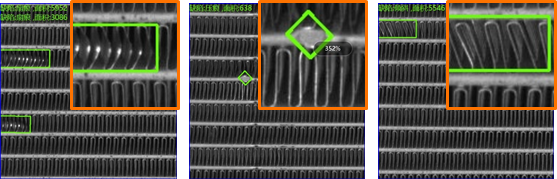

Considering the shape of the product and the organization of the site, the scheme selected 2K linear array camera for map collection, with high-light linear array light source, to highlight the product detection characteristics.

3). Program advantages:

1. Use deep learning algorithm to detect defects and judge defect categories. Through defect collection and model iteration, the comprehensive recognition rate reaches more than 99%, and the inspection control is less than 2%.

2. category judgment of defects, reverse promote customer process improvement and promotion.