The manufacturing process of the automobile industry has achieved a high degree of automation, ensuring the efficiency and safety of the production process is the primary goal of automobile manufacturers. Machine vision products can effectively improve the reliability of products at all stages of the automotive manufacturing and assembly process to meet the stringent quality requirements of the automotive industry.

Share

Industry overview

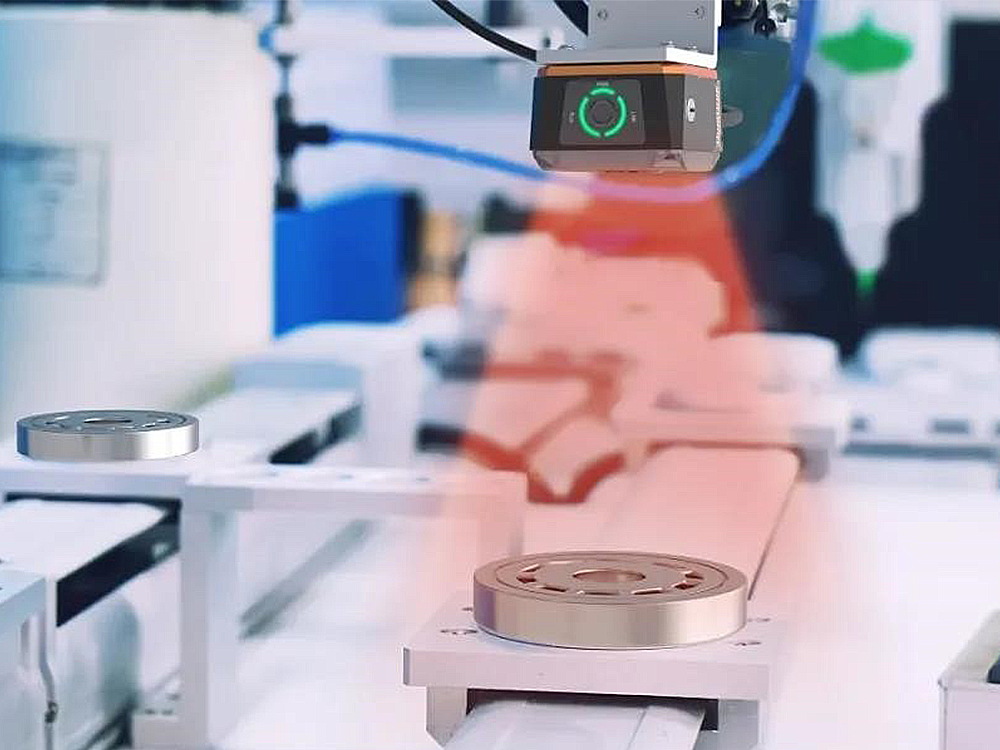

Automobile final assembly and parts testing

Check the appearance, position, code system and assembly correctness of auto parts.

In many aspects of automobile manufacturing, unmanned operation has been achieved, which requires a reliable detection technology to verify the correctness of each assembly and the conformity of assembly parts, and machine vision technology has become the first choice for automatic detection systems with its unique technical advantages. Among them, automotive assembly and parts testing include parts size, appearance, shape; Assembly component error and missing installation, direction, position detection; Code reading, model, production date testing; Assembly with robot welding guidance and quality inspection; Electrical performance testing, functional testing; License plate recognition in intelligent transportation..

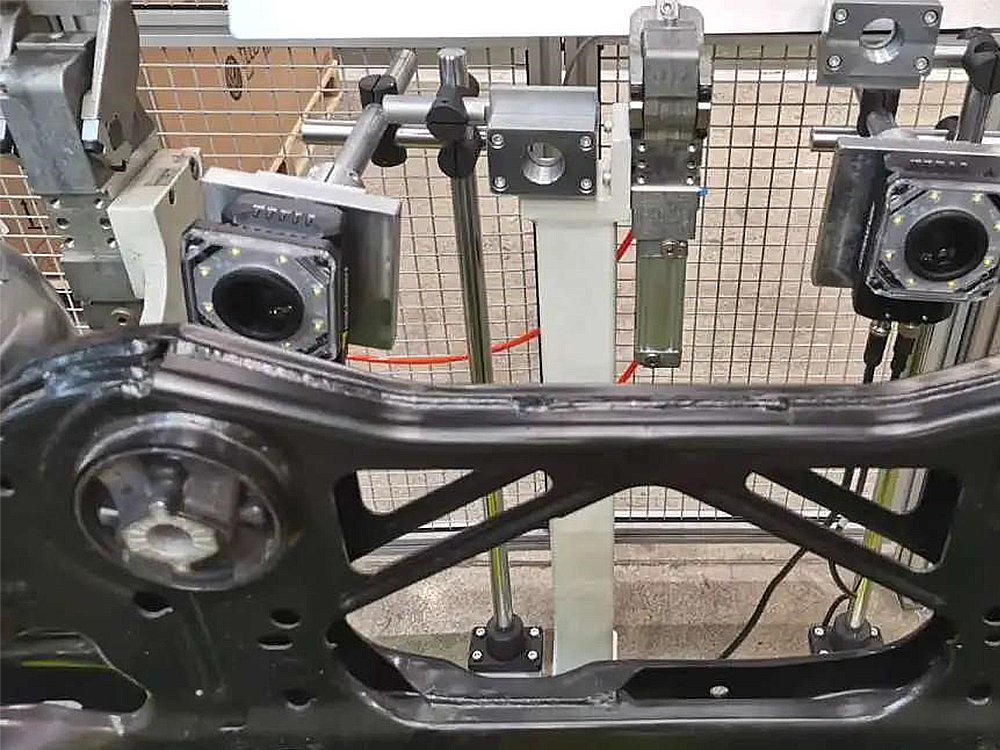

Engine Detection

Detect the position, size, character and model of the automobile engine and its components.

Machine vision is widely used in all aspects of automobile production and manufacturing. The automobile engine is the device that provides power for the automobile and is the heart of the automobile. The detection content mainly includes the machining position, shape and size, including the arc; Timing chain position detection; Piston marking direction and type detection; Crankshaft connecting rod code, character, type detection; There is no detection of dispensing; Cylinder head reading, character, type detection.