The built-in deep learning core RGB-D intelligent stereo camera is paired with the robot, and through the organic combination of deep learning algorithm and traditional vision algorithm, the robot is guided to grasp efficiently all the time.

Share

1). Project background:

Requirement description:

1. Use visual and belt control instead of manual supply.

2. need to be compatible with carton, soft bag, snakeskin bag, envelope and other types of packages.

3. need to achieve package positioning, separation, de-stacking functions.

4. Ensure that the packages are not stacked or overstocked and pass through individually.

Technical requirements:

1. package height range :10~500mm.

2. real-time processing time ≤100ms.

3. separation success rate > 99%.

4. system processing efficiency > 4000 pieces/hour.

2). Solution architecture:

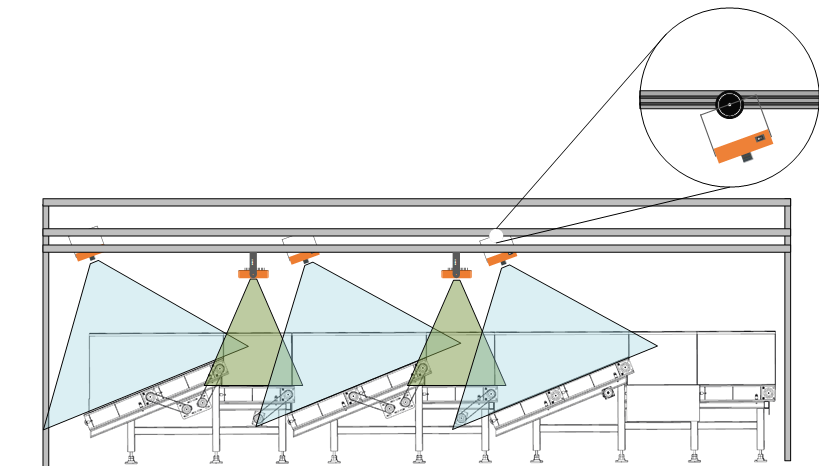

Aiming at the problems of high cost, package stacking and low efficiency, the climbing de-stacking system adopts color industrial camera + high-performance host solution and advanced deep learning algorithm to complete accurate package positioning for a large number of packages stacked and a wide variety of complex scenes, and then controls the belt to execute commands to separate the packages. The post-stack section can be matched with single piece separation, double correction and multi-side reading to achieve automatic package reading and sorting, truly reducing staff and increasing efficiency.

3). Program advantages:

1. scientific scheduling: self-developed intelligent control system, the package optimal control arrangement, to ensure the effective separation of stacked packages, reduce the back end of the wrong parting pressure.

2. reduce staff and increase efficiency: each set of climbing and stacking system replaces 2 labor, the maximum efficiency is close to 2000 pieces/hour, to meet the cross-belt full sorting efficiency requirements.

3. Stable and reliable: Based on deep learning algorithm, it is not afraid of complex packages such as soft bags, black bags and envelopes, and provides accurate positioning.

4. strong expansion: the back-end can access single-piece separation, EDP, six-side reading and other automation equipment to complete a complete set of cross-tape automatic package solution.