In the production process of instant noodles, the packaging line automatically drops the spoon, but there is a certain probability that there will be multiple spoons or slotted spoons, thus affecting the normal use of instant noodles.

Share

1). Project background:

Requirement description:

In the production process of instant noodles, the packaging line automatically drops the spoon, but there is a certain probability that there will be multiple spoons or slotted spoons, thus affecting the normal use of instant noodles. At present, each station arranges two manual inspection, the labor cost is high, and the detection stability is poor, and the efficiency is low. The factory hopes to introduce machine vision to replace human labor and upgrade production lines.

Technical requirements:

The production beat must be greater than 6 packets /s.

The missed detection rate should be less than 0.01%.

2). Solution architecture:(方案架构)

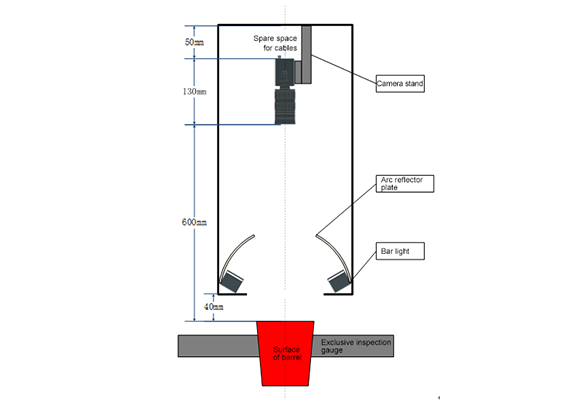

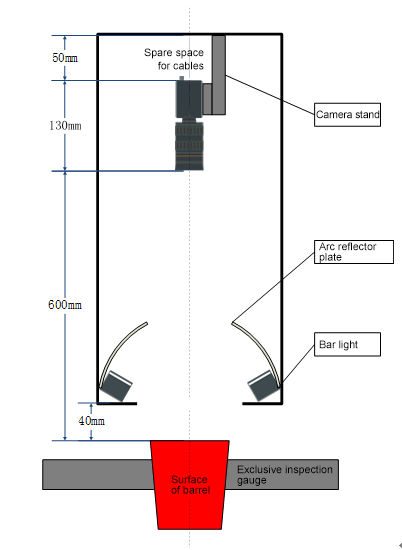

1.Erection scheme diagram:

2. imaging renderings:

3). Program advantages:

The fork posture is diverse, the position is random, and it will be blocked by the material package to different degrees. The brightness of the image will change after the light source is used for a long time. After the introduction of deep learning solutions, the overall performance has been further improved.

Be manifested in:

1. Overcome the problem that the color of instant noodles fork is close to that of flatbread.

2. overcome occlusion, light decay and other scene transformation problems.

3. excellent recognition accuracy, miss rate is less than 0.01%.

4. high detection efficiency, the algorithm takes less than 30ms.