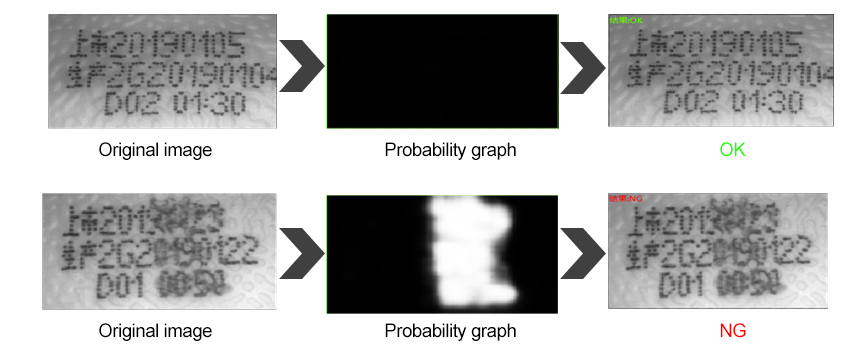

Due to the cleaning of the nozzle, the vibration of the machine, high temperature and other effects, the characters printed will appear incomplete, distorted and scratched.

Share

1). Project background:

Requirement description:

Dairy packaging is generally used in the form of ink to print the production label, the application site due to the cleaning of the nozzle, the vibration of the machine and the impact of high humidity, the printed characters will appear incomplete, distorted and scratched. The retail end of the product strictly controls the information of the third phase of production, and does not allow any defects, blurriness, dirt, etc., so the visual inspection program is introduced.

Technical requirements:

1. The missed detection rate is less than 0.03%

2. production beat 4 bottles /s

2). Solution architecture:

3). Program advantages:

Due to the complex and diverse forms of defects, the production date changes in real time, and the traditional way is difficult to detect character defects, so the deep learning method is introduced to solve the industry problems. The actual character defect detection rate is over 99.7%.