Before die cutting/slitting/laminating/winding, the linear array camera is used to detect the defects on the front and back of the anode and cathode to ensure the yield. And all the electrode defect detection requirements and standards are similar.

Share

1). Project background:

Requirement description:

Detection and classification of pole surface defects

The minimum accuracy required is 0.2mm²

Technical requirements:

Positive and negative defect detection items and specifications are as follows:

Electrode leakage foil < 1mm×1mm

Black dot white dot < 3mm

Dark mark < 10mm×1mm

Bubble < 1mm×1mm

Length of white line < 40mm

Yellow test 15mm×15mm

The tape is detected immediately

Pit/indentation width < 4mm

Unrolled is detected

Edge drop width ≤0.2mm

Pole crumpling depends on the situation

Adhesive is detected as soon as it is present

Black stripe/black line length < 40mm

Dirt depends on the situation

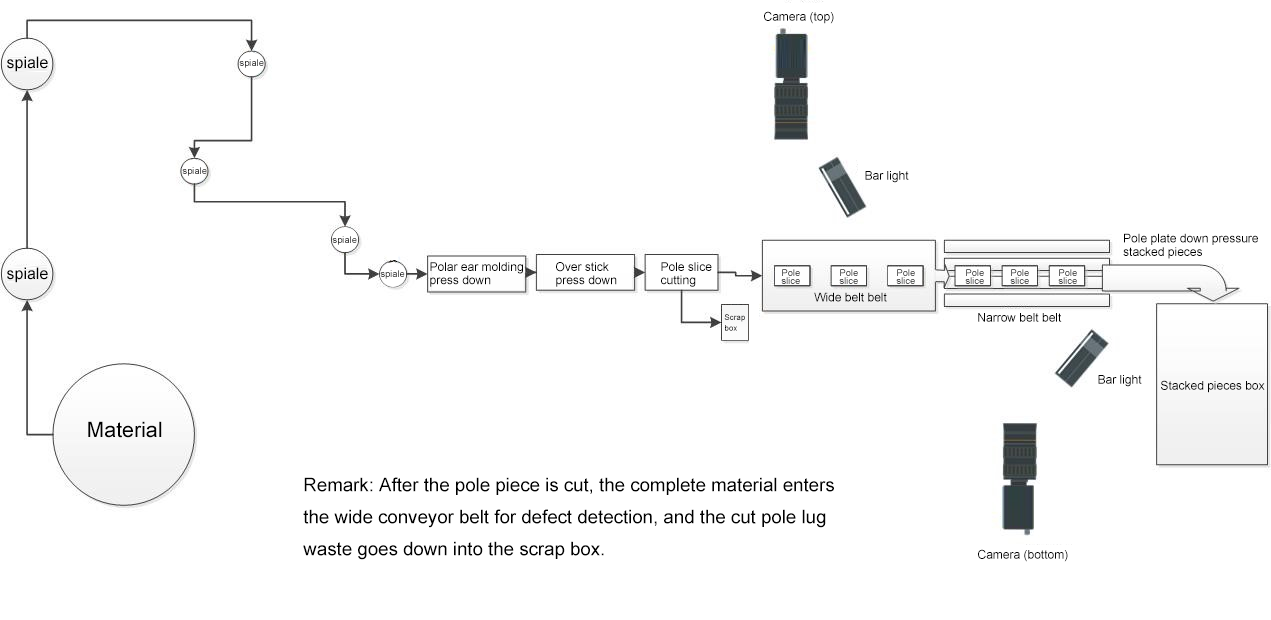

2). Solution architecture:

Scheme description:

The belt/roller drives the motion of the pole film, stops and runs alternately, and uses the frame plus line trigger mode to control the drawing of the line scan camera. Two 8K line scan cameras (with different resolutions according to different pole width) are selected to take a picture of the front and back of the pole film each time. The theoretical accuracy of single pixel can be within 0.05mm/pixel. This scheme can be promoted in the defect detection part of die-cutting, coating, lamination and other processes. According to the different design of the mechanism, the installation method is slightly different.

Erection diagram:

3). Program advantages:

1.Support the combination of traditional algorithms and deep learning, and adopt the optimal solution for different defects;

2.support the classification function of all detected defects, and can open the detection conditions according to customer requirements;

3.the algorithm processing efficiency is high, the large image processing speed is stable at a low level, to meet the high-speed conditions of the lithium battery industry;

4.customized functions, including but not limited to data according to cell transmission, light source adaptive, defect spot detection, automatic process value acquisition, three-level authority, automatic save and delete, reset and re-cut and other practical functions. It is convenient for debugging personnel to get started and help save customer materials.