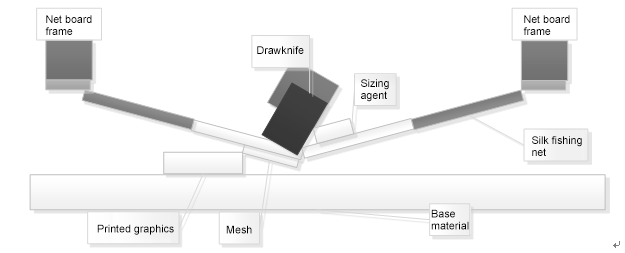

Screen printing is the key process of battery manufacturing, visual positioning of the printing position to guide the UVW platform printing, and re-inspection of defects after printing.

Share

1). Project background:

Requirement description:

Positioning requirements: Shoot the four corners or Mark points of the silicon wafer, locate the printing position, and guide the UVW platform printing;

Detection requirements:

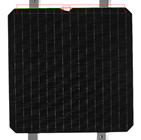

1.detection of battery edge damage;

2.detect the dirt on the battery, such as ash, fingerprints, etc.;

3.Recheck whether the printed battery is cracked or broken.

Technical requirements:

Static accuracy is about ± 0.005mm, dynamic accuracy is about ± 0.015mm.

2). Solution architecture:

The positioning vision system consists of 5MP resolution industrial camera, HF series industrial lens and ring light source.

2K line scan industrial camera, KF lens and line light source constitute the inspection vision system.

3). Program advantages:

1.high precision, through black and white checkerboard calibration, correction of radial distortion and perspective distortion.

2.low consumption, positioning process time ≤150ms, edge detection process time ≤200ms.

3.Based on VM platform, with a wealth of high-performance algorithm modules, positioning algorithm based on feature matching, edge defect detection algorithm based on linear defect detection tools.

4.cost-effective camera solution, low cost, high performance.