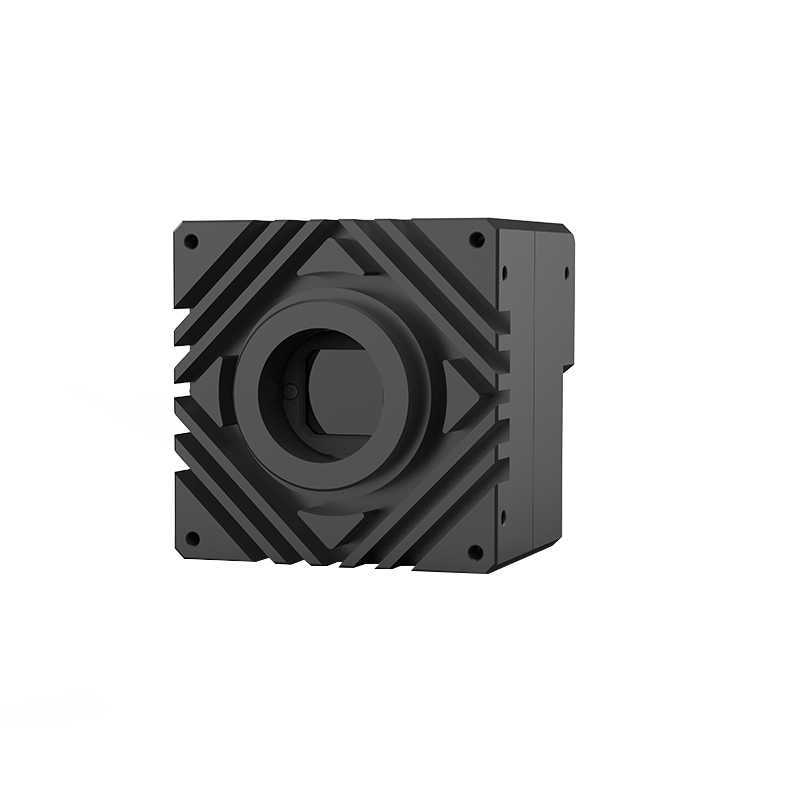

Machine vision cameras are now of great relevance within the manufacturing sector as well quality inspection processes in industries. Through the use of these modern imaging systems, automation and efficiency are made possible, which are indeed very important in today’s world. Such settings also exist in our newer development HIFLY machine vision cameras tools that suit various industrial purposes. Technology advances have made it easier to create cameras that do not only permit the viewing of objects, but provide clear images that make inspection and measurement easier and more objectives.

Machine vision cameras have really been transformed in terms of their functionality. The first generation of machine vision cameras was rudimentary and their applications were restricted. Fast forward to today, and the scenario is completely different - cameras can offer great picture quality with impressive features such as real time processing capabilities, multiple ports and sensors as well as performing functions under different lighting conditions. HIFLY machine vision cameras are ideal for harsh conditions, so their reliability and longevity are guaranteed.

With the shift towards automation by different sectors, the need for advanced machine vision solutions is on the rise. HIFLY pays careful attention on the future trends of this technological development. Our objective is to take advantage of the advancement of technology to create machine vision cameras that not only meet the demands of our customers, but also go beyond them. HIFLY in this regard is focused on quality and constant improvement remaining a reliable partner for companies wishing to transform their manufacturing capabilities with cutting-edge vision solutions. HIFLY’s clients secure their competitive edge in a rapidly evolving market by future-proofing their business processes with HIFLY’s solutions.