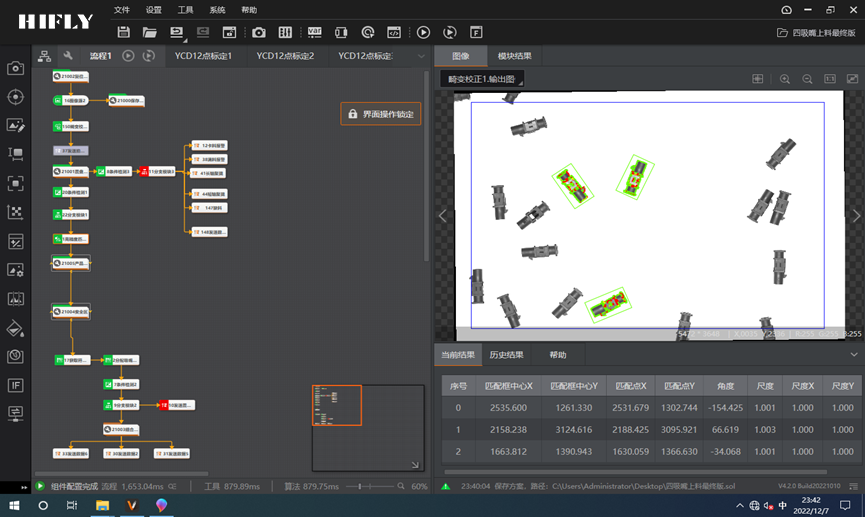

The materials are dispersed through the vibrating disk, and the materials that meet the requirements are screened by vision first, and then visually positioned

Share

1). Project background:

Requirement description:

The project uses the VM algorithm development platform to realize the loading and grabbing of various materials. The materials are dispersed through the vibrating disk, and the materials that meet the requirements are screened by vision first, and then visually positioned. The difficulty of the project is how to optimize the accuracy of 360-degree full-angle grasp of compatible special-shaped parts.

Technical requirements:

(1) To achieve vibration disk product absorption, positioning accuracy of ±0.25mm

(2) Judge the direction of the material and distinguish the left and right directions

(3) Need to screen out the upper and lower direction of the material, not for the positive side up can not grab

(4) The safety zone function needs to screen the materials close to the vibration disk

(5) Need to screen out the mix, not for the same material can not grab

2). Solution architecture:

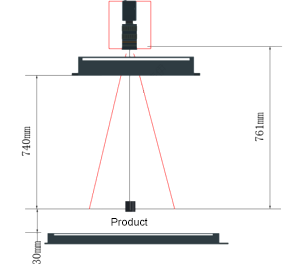

The scheme uses the front light source and the back light, prints the material outline, and matches the FA lens to meet the needs of high working distance and large depth of field.

3). Program advantages:

1. the automatic feeding function of shaped parts is realized, and the missing grasp rate is less than 0.1%

2. VM visual image algorithm processing performance is good, with the customer high-speed manipulator to take materials, can achieve 7200 pcs/h high-speed feeding requirements

3. VM algorithm platform standard software development, do not need complex programming, do not need software engineers to complete the project construction, for enterprises to reduce the difficulty of development and after-sales maintenance costs