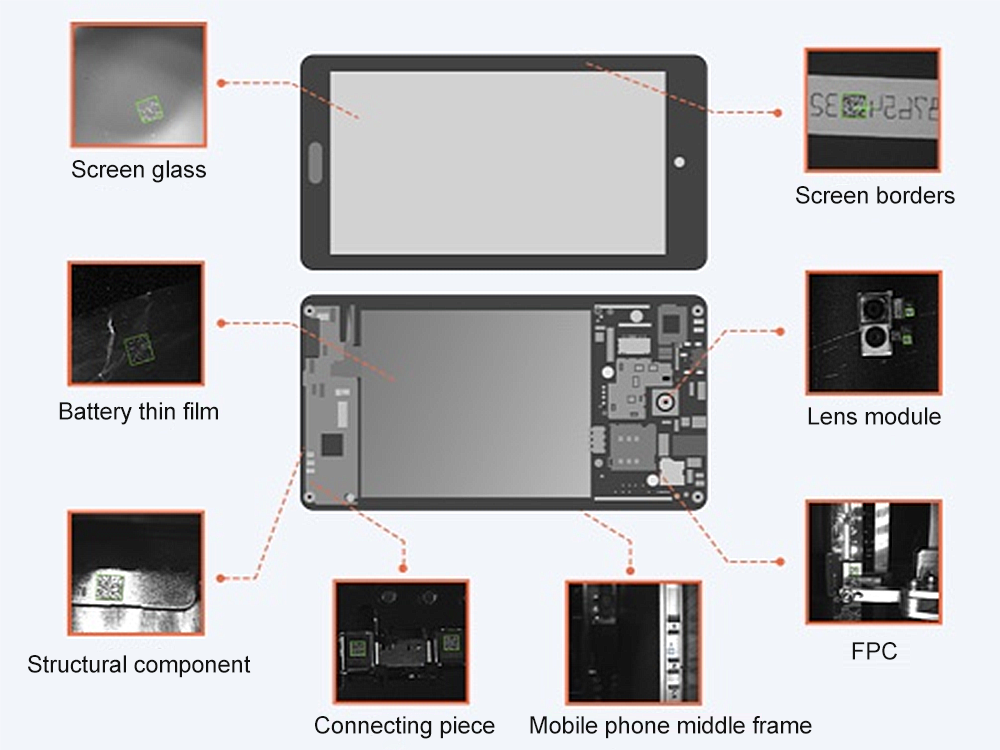

As the largest field of machine vision application in China, 3C electronics can see the figure of machine vision in all links of the electronic manufacturing industry chain, as small as imaging modules, USB connectors, and as large as mobile phone frames, PC motherboards and other devices. It includes application scenarios such as processing and assembly of connectors, screen alignment and fitting, and flat plate scratch detection.

Share

Industry overview:

1.Positioning guidance

The position information of the tested object is obtained by machine vision technology, and the robot is guided to perform a series of operations.

Based on image calibration, target detection, size search and other algorithm technologies, the main role in robot guidance related applications is to accurately obtain the coordinate position and Angle of the object (grab object) and the object (object to be assembled), and convert the image coordinates into robot coordinates that can be recognized by the robot, and guide the robot for positioning and assembly.

2. Code recognition

Electronic industry product process is complex, in some links of the industrial chain, the identification of product ID information.

Demand for electronic devices such as smartphones and tablets has soared. With the increasing number of parts and the accelerating development of product miniaturization, manufacturers are also committed to the pursuit of high-quality traceability management. In view of the miniaturization of electronic parts, in many cases, the traditional contact engraving processing method has been changed to non-contact high-precision laser engraving and processing. Therefore, the requirements for subtle, high-quality, low-damage engraving traceability are also increasing.

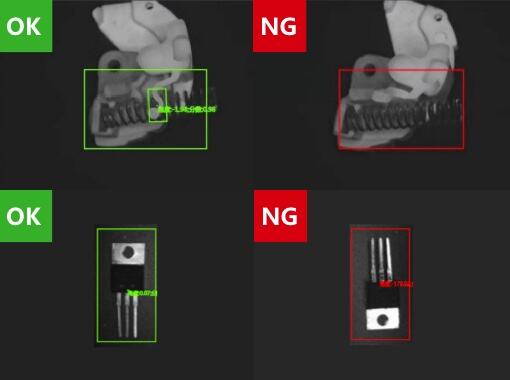

3. Defect detection

Detect scratches, damage, spots, color difference and other defects on the surface of electronic products.

Electronic industry in the process of manufacturing products, can not avoid defects, and production enterprises on product quality requirements are increasingly high, therefore, defect detection is a very important application in the industry, machine vision has high precision, high speed detection capabilities, can achieve a variety of defects detection, including scratches, damage, spots, color difference and so on.