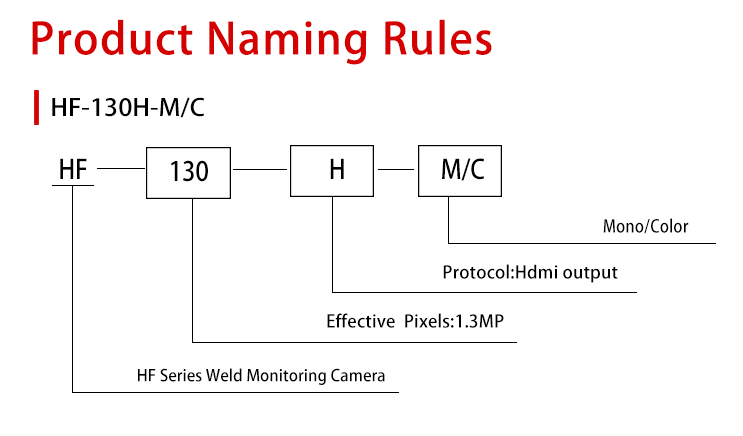

HF-130H-M/C Weld Monitoring Camera 1/2.7" 1.3MP

|

HIFLY weld monitoring camera is an advanced tool specifically designed for monitoring and controlling the welding process. |

|

● Resolution of 1280x1024@60fps. |

|

● No need fora computer,directly connect the camera to a display screen. |

|

● Plug-and-play functionality,ready to use. ● Uses fiber optic HDMI cables to avoid electromagnetic fields and high-frequency interference. ● Uses wireless image transmission, optional battery power supply, avoid cable clutter, more convenient for robot welding. |

| Model | Sensor Type | Effective Pixels | Max Resolution | Frame Rate | Shutter | Protocol | Operation System Software | Lens | Working Distance | Color | Dimension |

| HF-130H-M/C | B&W1/2.7CMOS imager | 1.3MP | 1280x1024 | 60fps | Global | Hdmi output | No need for computer | F=25mm(Builded-in) F=42mm(Interchangeable) |

160-250mm(F25mm len) 200-450mm(F25mm len) |

Mono/Color | 45x45x62mm |

| HF-130UM/C | 1/2.7CMOS imager | 1.3MP | 1280x1024 | 206fps | Global | USB3.0/U3Vison/GenlCam | Win7/Win10/Android | F=25mm(Builded-in) F=42mm(Interchangeable) |

160-250mm(F25mm len) 200-450mm(F25mm len) |

Mono/Color | 45x45x62mm |

| Please contact us learn more models ! | |||||||||||

| Model | HF-130H-M/C |

| Product name | Weld Monitoring Camera |

| Sensor | 1/2.7", CMOS |

| Effective Pixels | 1.3MP |

| Max Resolution | 1280x1024 |

| Pixel Size | 5.6 * 5.6 μm |

| Color | Mono/Color |

| Shutter | Global |

| Frame rate | 60fps |

| Protocol | Hdmi output |

| Feature | No pictures or videos can be stored |

| Operation System Software | No need for computer,Live broadcast type |

| Lens | F=25mm(Builded-in) F=42mm(Interchangeable) |

| Lens Mount | C-Mount |

| Working Distance | 160-250mm(F25mm len) 200-450mm(F25mm len) |

| Configuration | / |

| Working Temperature | -40°C—85°℃ |

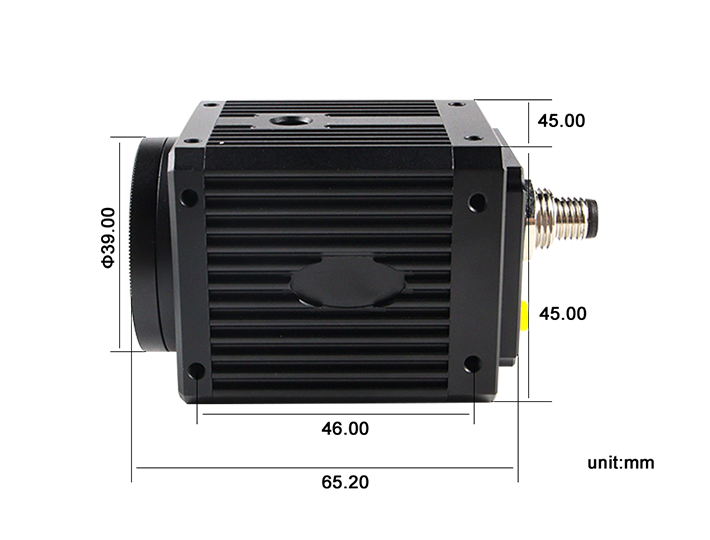

| Dimension | 45x45x62mm |

| Net Weight | 120g |

Welding monitoring of metal cylinder body wall

After installing the welding monitoring camera, the operator can directly observe the tungsten electrode, arc and melting state from a long distance. There is no need to drill into the cylinder, which reduces the labor intensity and improves the safety.

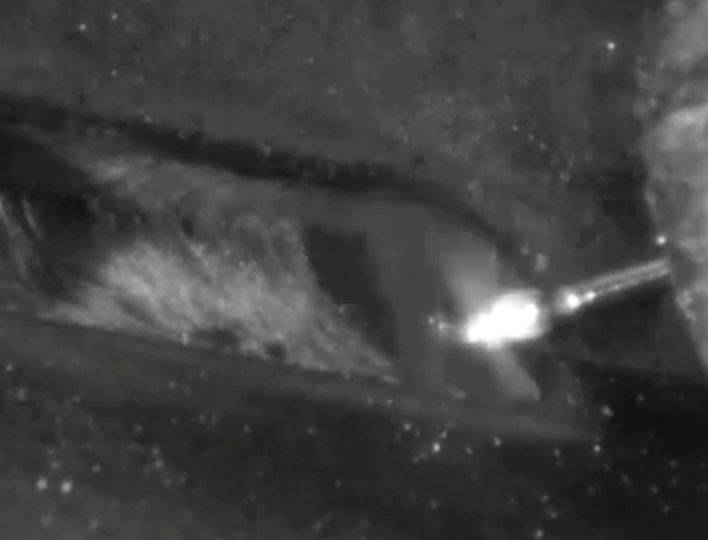

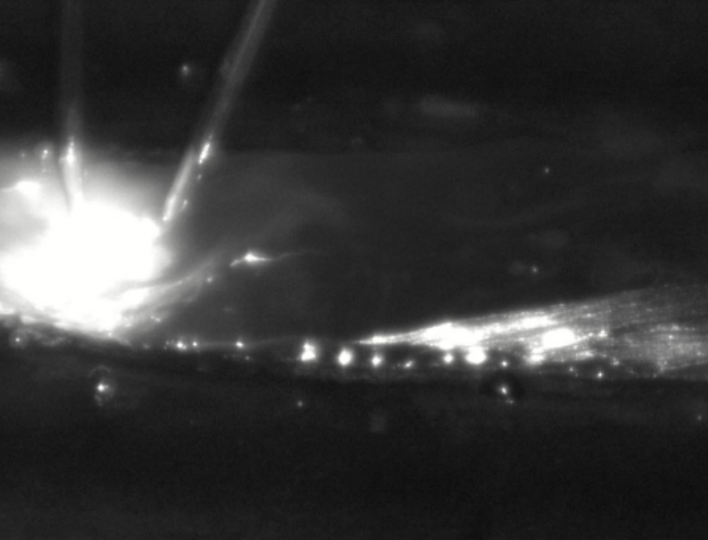

TIG welding and MIG welding monitoring

The welding monitoring camera can monitor the effect of TIG welding and MIG welding in different welding methods, including the welding process monitoring of carbon steel, stainless steel and other materials.

Twin wire welding monitoring

Real-time and accurate detection of quality problems in the welding process.Such as whether the welding wire is sufficient, whether the welding position is correct, and whether the welding temperature is up to standard, so as to ensure the quality of the welding is stable.

Welding monitoring in harsh ring mirror

When welding operations are carried out in high temperature, high pressure, and toxic and harmful environments, the use of welding monitoring cameras can effectively protect the body safety of welders and avoid accidents caused by negligence or operation errors.

Q1. Can I have a sample order for Weld Monitoring Camera?

A: Yes, sample orders and any orders are acceptable.

Q2. What is the lead time?

A: 3-5 days for sample/small(<50pcs) orders, 1-2 weeks for bulk buying (>50pcs).

Q3. What's your MOQ for the Weld Monitoring Camera ?

A: The MOQ is 1pcs.

Q4. What's your shipment term and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 5-7 days by air. Shipping by sea is also acceptable.

Q5. How to place an order for Weld Monitoring Camera ?

A: 1. Confirm parameters such as FOV and WD;

2. Confirm the shape, state, material and color of the detected object;

3. Confirm the order and quote;

4. Pay orders and arrange production;

5. Check the product and arrange delivery.

Q6. Do you support private labels?

A: Yes, we do.

Q7: How long is your product warranty?

A: We offer 2-5 years warranty for our products.

Q8: How do you deal with the faulty products?

A: 1, Our products are produced in strict quality control system with a 0.2% defective rate.

2, If non-artificial damage, dysfunction or errors happen during the warranty period, customers can go for repair, replacement or partial/full refund.

HF-130H-MC(Specifications & Drawings).pdf

download