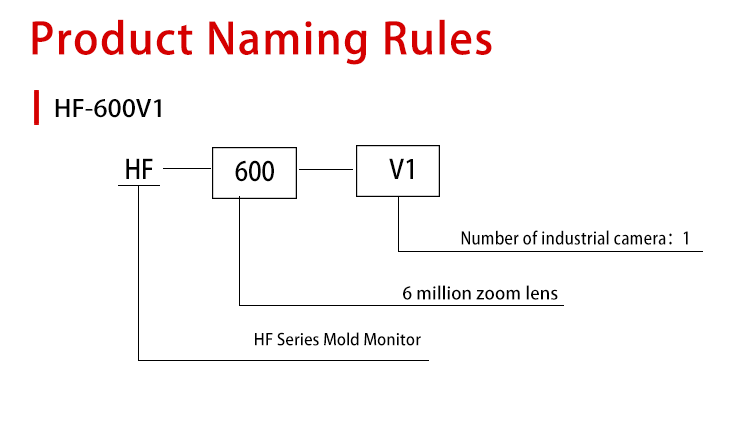

HF-600V1 Mold Monitor Inspection Systems

|

HIFLY mold monitor mainly detects various possible problems encountered in the production process of injection molds to avoid mold compression and damage caused by products not taken off, thimbles, sliders or residues. |

|

● 13.3-inch display (1920*1080 HD display), Resistive touch. |

|

● Support 1-4 HD industrial cameras. |

|

● 6 million zoom lens (7-36mm/5-50mm). ● Linux operating system, long time work does not crash, No copyright disputes, no viruses. ● Gigabit Ethernet interface, POE power supply, strong anti-interference ability. ● Multi-machine networking, the establishment of mes system. |

| Model | HF-600V1 | HF-600V2 | HF-600V3 | HF-600V4 |

| 13.3 inch industrial integrated mainframe | 1 | 1 | 1 | 1 |

| Industrial camera | 1 | 2 | 3 | 4 |

| Industrial lenses | 1 | 2 | 3 | 4 |

| Infrared light | 1 | 2 | 3 | 4 |

| Magnetic base | 2 | 4 | 6 | 8 |

| Inch screw + camera fastener | 1 | 2 | 3 | 4 |

| Host power + cable | 1 | 1 | 1 | 1 |

| Monitor stand | 1 | 1 | 1 | 1 |

| Magnets + matching screws | 4 | 4 | 4 | 4 |

| Light source extension cable | 1 | 2 | 3 | 4 |

| Gigabit cable | 1 | 2 | 3 | 4 |

| Injection molding machine DB15 link line | 1 | 1 | 1 | 1 |

| Cannula | 1 | 2 | 3 | 4 |

| Specification | 1 | 1 | 1 | 1 |

| Please contact us learn more models! | ||||

| Model | HF-600V1 |

| Type | Mold Monitor |

| Industrial integrated mainframe | 1 |

| Industrial camera | 1 |

| Industrial lenses | 1 |

| Infrared light | 1 |

| Brand Name | HIFLY |

| Place of Origin | Guangdong, China |

| Customized support | OEM, ODM, Software reengineering |

| Warranty | 1 Year |

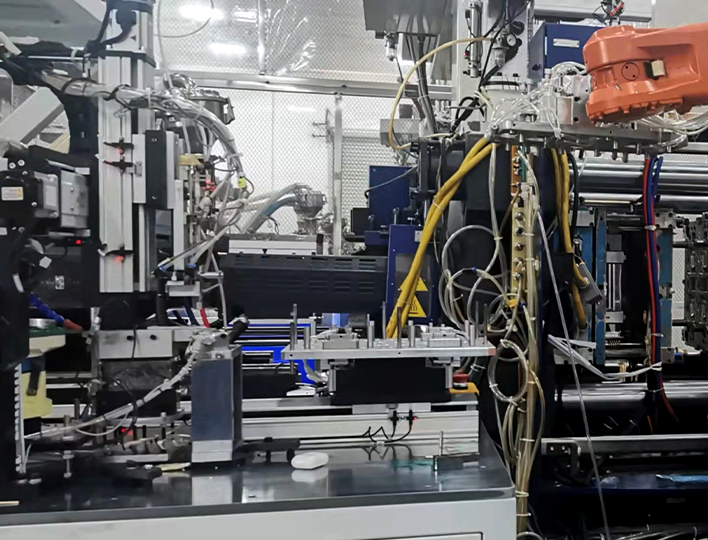

Electronic precision product detection

The mold monitor determines whether the mold is working properly by observing whether there is obvious damage or wear on the appearance of the electronic product mold. The molds need to be repaired and replaced when they are defective.

Automatic visual positioning detection

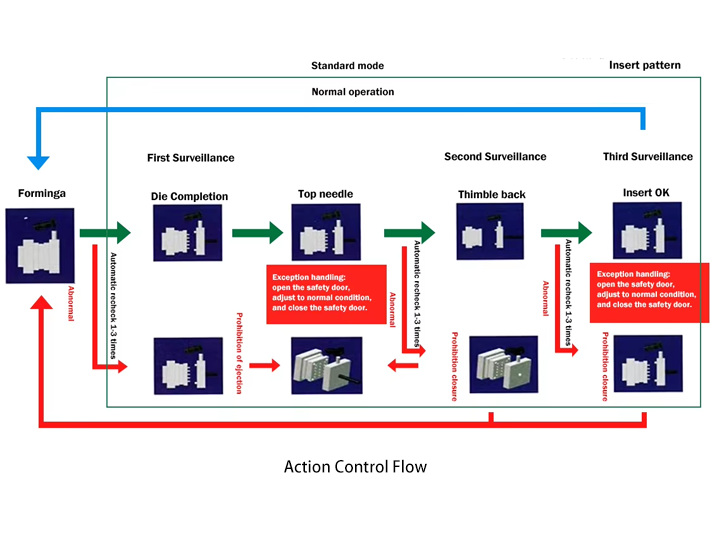

In the process of injection molding production, the injection molding machine completes the mold opening action and reaches the predetermined position. The mold monitor will send a confirmation signal, and the injection molding machine will enter the next production cycle after receiving the instruction.

Multi-mode and multi-hole simultaneous detection

Multi-mode and multi-hole molds have more holes and details in the production process, mold monitor system can monitor the production process in real time. When the mold is damaged or the thimble is not returned, the alarm signal is sent out in time to terminate the production.

Automated robot in-die and out-die inspection

In automated robot production, when the workpiece fails to fall smoothly in the preset time or there is a foreign body in the mold cavity, the mold monitor will immediately identify the abnormal situation. A stop signal is issued to suspend the operation of the injection molding machine and trigger the alarm system.

Q1. Can I have a sample order for Mold Monitor?

A: Yes, sample orders and any orders are acceptable.

Q2. What is the lead time?

A: 3-5 days for sample/small(<50pcs) orders, 1-2 weeks for bulk buying (>50pcs).

Q3. What's your MOQ for the Mold Monitor?

A: The MOQ is 1pcs.

Q4. What's your shipment term and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 5-7 days by air. Shipping by sea is also acceptable.

Q5. How to place an order for Mold Monitor?

A: 1. Confirm parameters such as FOV and WD;

2. Confirm the shape, state, material and color of the detected object;

3. Confirm the order and quote;

4. Pay orders and arrange production;

5. Check the product and arrange delivery.

Q6. Do you support private labels?

A: Yes, we do.

Q7: How long is your product warranty?

A: We offer 2-5 years warranty for our products.

Q8: How do you deal with the faulty products?

A: 1, Our products are produced in strict quality control system with a 0.2% defective rate.

2, If non-artificial damage, dysfunction or errors happen during the warranty period, customers can go for repair, replacement or partial/full refund.

Mold monitor-User manual-2024.pdf

download