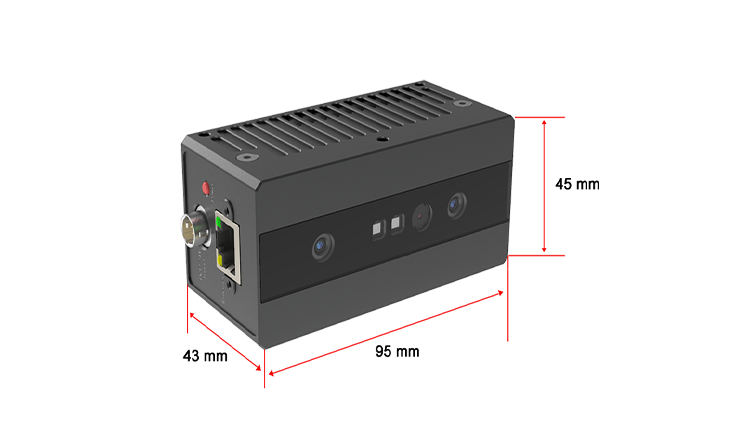

HF-820 3D Depth Camera 300~1400mm

|

The HIFLY 3D depth camera IP41 includes two infrared (IR) sensors, one RGB sensor and two structured-light projectors. |

|

● Accuracy(Z): 1.73mm@1500mm. |

|

● Accuracy(X,Y): 4.88mm@1500mm. |

|

● State of use: static measurement. |

|

● Upgraded SGBM algorithm with built-in hardware lSP. |

|

● Match SDK and RVS software. |

| Model | Measurement range(mm) | FOV(H/V) | Z Accuracy(mm) | X/Y Accuracy(mm) | Power&Trigger |

| HF-811 | 700 ~ 3500 | 60°/48° | 4.85mm@2000mm | 8.23mm@2000mm | 6-pin aviation plug |

| HF-851 | 700 ~ 6000 | 58°/48° | 4.27mm@1500mm | 14.41mm@1500mm | 6-pin aviation plug |

| HF-820 | 300 ~ 1400 | 66°/44° | 1.73mm@700mm | 4.88mm@700mm | HR10A-7P-6S (HRS) |

| HF-815-E1 | 400 ~ 8000 | 60°/48° | 1.56mm@1000mm | 3.2mm@1000mm | 8-pin aviation plug |

| HF-461 | 100 ~ 1000 | 65°/50° | ±5+1% of depth [400, 2200] | HR10A-7P-6S (HRS) | |

| ±15+1% of depth (2200, 4300] | |||||

| Please contact us learn more models! | |||||

| Model | HF-820 |

| Working distance | 0.3m-1.4m |

| FOV(H/V) | 66°/44° |

| Accuracy(Z) | 1.73mm@1500mm |

| Accuracy(X,Y) | 4.88mm@1500mm |

| Depth resolution | 1280*800 |

| RGB resolution | 1920*1080 |

| Power Supply | DC 12V / 24V |

| Power supply and trigger interface | HR10A-7P-6S (HRS) |

| Data interface | RJ45 |

| Power consumption | 2.8W ~ 3.9W |

| Temperature | Storage:-10℃~55℃;Controls:0℃~45℃ |

| Protection level | IP41 |

| Size | 95mm*45mm*43mm |

| Weight | 228g |

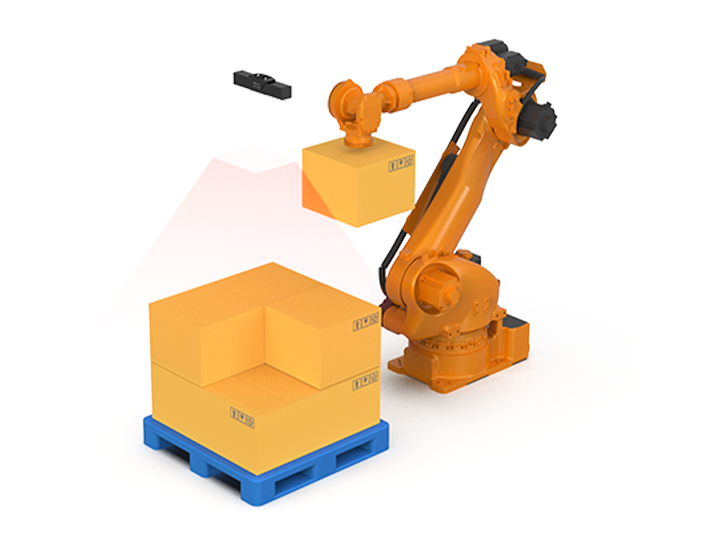

Palletizing / De-palletizing

3D industrial cameras capture depth information and contours of goods, combined with automated equipment such as robotic arms, to achieve automatic grasping, handling, and stacking of goods.

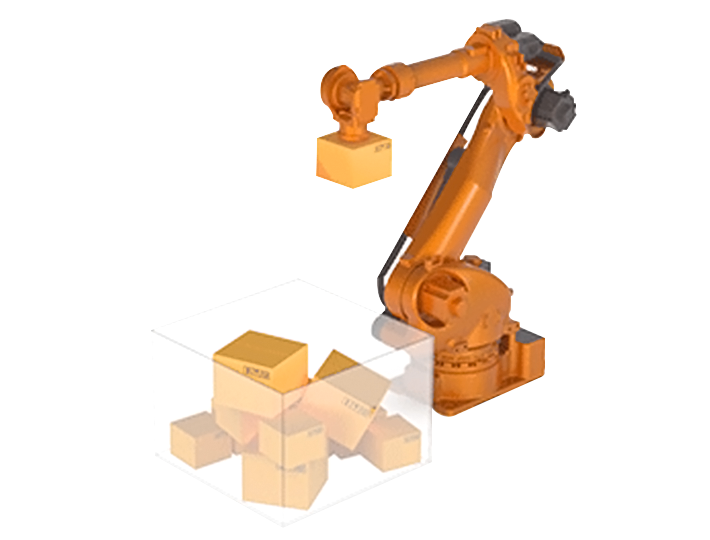

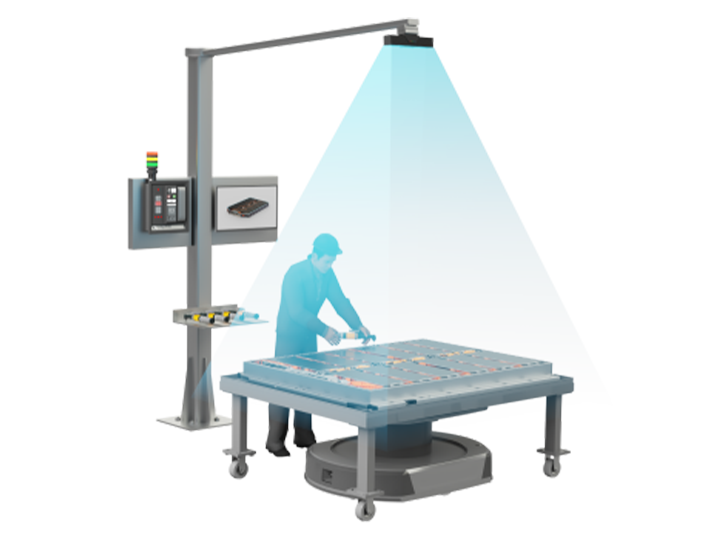

Industrial disorderly sorting

3D structured light imaging system scans the surface contour of the object to form a point cloud data. The real-time spatial coordinates of the current workpiece are calculated to guide the robot to complete the automatic grasping task.

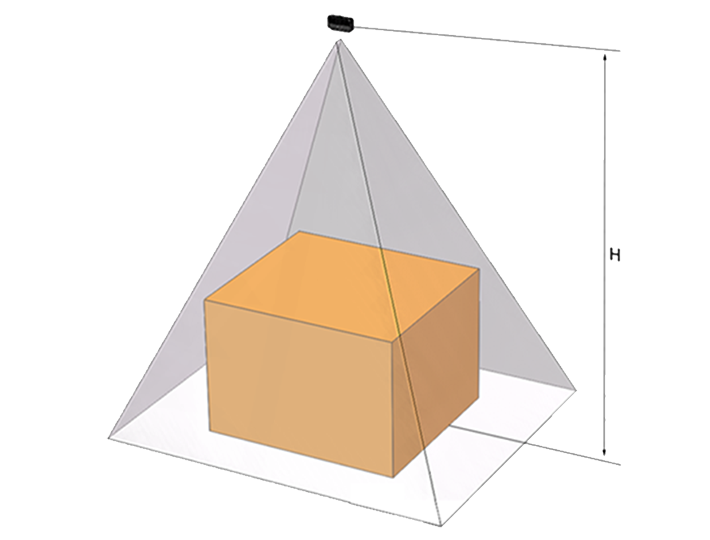

Static Volume Measurement

The 3D camera captures the 3D point cloud data of the object being measured for analysis, and calculates the length, width, and height data of the object to achieve static volume measurement.

Fastener positioning error detection

By using a high-speed, high-precision, long-distance, and wide field of view 3D camera, real-time positioning and tracking of mark points can be achieved, and the absolute spatial position and attitude angle from the mark point to the execution point of the electric gun tool can be mapped, reducing various operational errors.

Q1. Can I have a sample order for 3D Depth Camera?

A: Yes, sample orders and any orders are acceptable.

Q2. What is the lead time?

A: 3-5 days for sample/small(<50pcs) orders, 1-2 weeks for bulk buying (>50pcs).

Q3. What's your MOQ for the 3D Depth Camera?

A: The MOQ is 1pcs.

Q4. What's your shipment term and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 5-7 days by air. Shipping by sea is also acceptable.

Q5. How to place an order for 3D Depth Camera?

A: 1. Confirm the shape, state, material and color of the detected object;

2. Confirm the order and quote;

3. Pay orders and arrange production;

4. Check the product and arrange delivery.

Q6. Do you support private labels?

A: Yes, we do.

Q7: How long is your product warranty?

A: We offer 2-5 years warranty for our products.

Q8: How do you deal with the faulty products?

A: 1, Our products are produced in strict quality control system with a 0.2% defective rate.

2, If non-artificial damage, dysfunction or errors happen during the warranty period, customers can go for repair, replacement or partial/full refund.

HF-820(Specifications & Drawings).pdf

download