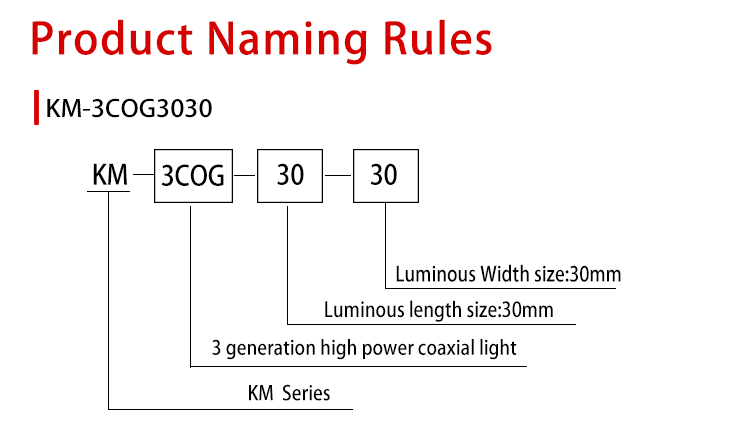

KM-3COG3030 High Power Coaxial Light DC 24V

|

HIFLY coaxial light consists of uniformly distributed LED light emitting units and special lenses. Support customized color, wavelength, luminescent surface size, etc. |

|

● Luminescent surface size: 30mm x 30mm. |

|

● Brightness level 255, connected to the controller can be adjusted. |

|

● Life span:30000 hours for red light and 30000 hours for white light. ● Suitable for Mark point positioning, QR code detection,uneven surfaces and Highly reflective object scratch detection, etc. |

| Model | Luminous size(mm) | Color | Voltage(V) | Power(W) | Boundary dimension(mm) | LED Type | |||

| Red | Blue/White | Length | Width | Height | SMD | ||||

| KM-3CO2020 | 20x20 | Red/Blue/White | 24V | 2.1 | 2.8 | 50 | 28 | 28 | √ |

| KM-3CO3030 | 30x30 | Red/Blue/White | 24V | 3.5 | 4.0 | 65 | 38 | 38 | √ |

| KM-3CO4040 | 40x40 | Red/Blue/White | 24V | 5.0 | 6.0 | 78 | 48 | 50 | √ |

| KM-3CO6060 | 60x60 | Red/Blue/White | 24V | 7.5 | 11.0 | 100 | 70 | 70 | √ |

| KM-CO2.0-3535 | 35x35 | Red/Blue/White | 24V | 2.6 | 3.4 | 70 | 44 | 47.5 | √ |

| KM-CO2.0-5050 | 50x50 | Red/Blue/White | 24V | 4.5 | 5.7 | 100 | 60 | 67.5 | √ |

| KM-CO2.0-7070 | 70x70 | Red/Blue/White | 24V | 6.0 | 11.0 | 110 | 82 | 84.5 | √ |

| KM-3COG3030 | 30x30 | Red/Blue/White | 24V | 7.0 | 9.0 | 79.5 | 38 | 38 | √ |

| KM-3COG4040 | 40x40 | Red/Blue/White | 24V | 13.0 | 14.5 | 95 | 48 | 50 | √ |

| KM-3COG6060 | 60x60 | Red/Blue/White | 24V | 27.5 | 18.0 | 127 | 70 | 70 | √ |

| Please contact us learn more models ! | |||||||||

| Model | KM-3COG3030 | ||

| Category | High power coaxial light | ||

| LED Type | SMD | ||

| Color | red | white | blue |

| Wavelength | 620-635nm | — | 465-470nm |

| Color-temperature | — | 6000-6500K | — |

| Power | 6.9Wmax. | 9.0Wmax. | 9.0Wmax. |

| Input Volt | DC24Vmax. | ||

| Cable length | 0.5m | ||

| Terminal Plug | Flat head 3PIN2 pin | ||

| Connector Definition | 1:positive(+)red; 2:leave empty; 3:negative(-)black. | ||

| Shell Material | Aluminum Alloy(Oxidative blackened surface) | ||

| Cooling | Naturalair cooling | ||

| Dimensions | L79.5mm x W38mm x H38mm | ||

| Shell Hardness Parameters | Static load 230N±10N,time 5 minutes contact area:diameter 30MM Energy level:5J elements: steel ball diameter 50MM,500g±25g |

||

| ElectricalIn Sulation Capacity | DC500V Insulation resistance>20 megohms | ||

| Pressure Resistance Requirements | AC1000 V10mA/5S | ||

| Flammability Rating | IEC60707 | ||

| Operating Temperatureand Humidity | Temperature:0 to 50ºC,Humidity:20% to 85%RH(non-condensing) | ||

| Lifespan | Under our specified conditions of use,30000 hours for red light and 30000 hours for white light,the brightness is reduced to 50% of the factory value | ||

| Warranty Period | Under the conditions of use specified by the company,the warranty is two years from the date of shipment,and within two years,if there is a failure problem, it can be repaired or replaced free of charge | ||

| Value Added Services | One year free technical support | ||

| Brightness Controller (optional) | 1.Analog Controller 2.Digital Controller | ||

| Matingcable (optional) | 1.Light source extension cable 2.Connector adapter cable | ||

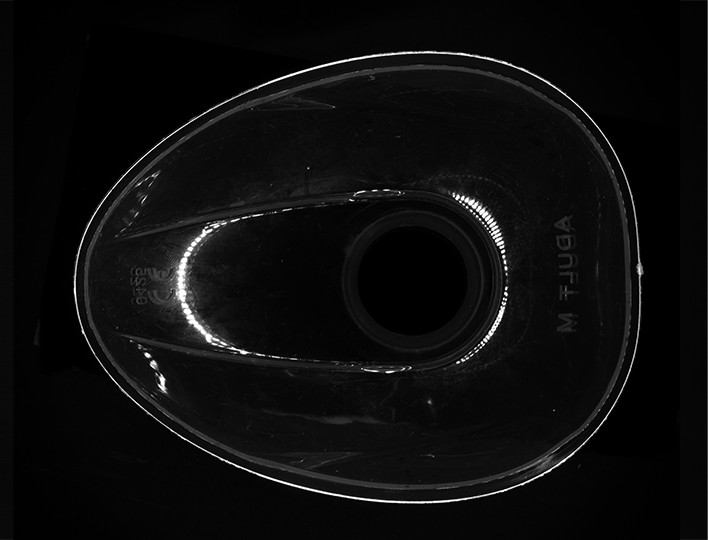

Transparent mouth cover scratch detection

The mouth cover is made of transparent plastic material, and the human eye cannot observe the fine scratches on the product. When using machine vision solutions for detection, the anti-reflection and strong light characteristics of coaxial light meet the detection requirements.

Glass edge defect detection

The manufacturing process of glass is complex, and the defects of glass cannot be observed by human eyes during production. In order to ensure product quality, machine testing is required before glass packaging to avoid defective products flowing into the market.

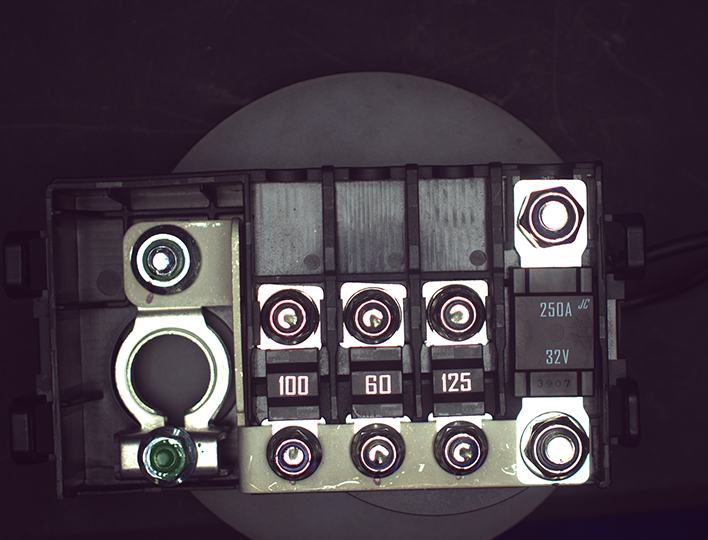

Electric box fuse position detection

There are three types of fuse in the electrical box, and the camera is still to trigger the photo. Visual inspection determines the fuse position according to the font in the image to check whether the product structure is complete.

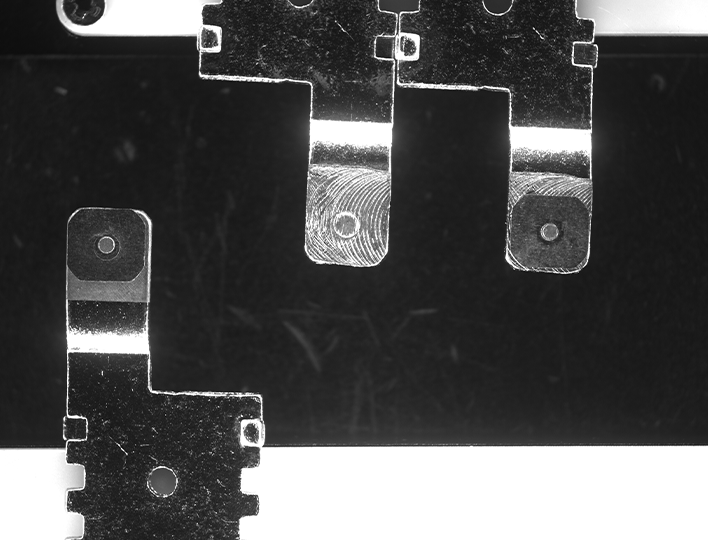

Metal solder joint detection

The top of a metal product needs to be welded with a small iron sheet, and the welding state is related to the overall appearance of the product. In order to ensure the quality of the product, it is necessary to inspect the product and observe the condition of the welding point when welding the small iron sheet.

Q1. Can I have a sample order for Coaxial Light?

A: Yes, sample orders and any orders are acceptable.

Q2. What is the lead time?

A: 3-5 days for sample/small(<50pcs) orders, 1-2 weeks for bulk buying (>50pcs).

Q3. What's your MOQ for the Coaxial Light?

A: The MOQ is 1pcs.

Q4. What's your shipment term and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 5-7 days by air. Shipping by sea is also acceptable.

Q5. How to place an order for Coaxial Light?

A: 1. Confirm parameters such as FOV and WD;

2. Confirm the shape, state, material and color of the detected object;

3. Confirm the order and quote;

4. Pay orders and arrange production;

5. Check the product and arrange delivery.

Q6. Do you support private labels?

A: Yes, we do.

Q7: How long is your product warranty?

A: We offer 2-5 years warranty for our products.

Q8: How do you deal with the faulty products?

A: 1, Our products are produced in strict quality control system with a 0.2% defective rate.

2, If non-artificial damage, dysfunction or errors happen during the warranty period, customers can go for repair, replacement or partial/full refund.

KM-3COG3030(Specifications & Drawings).pdf

download