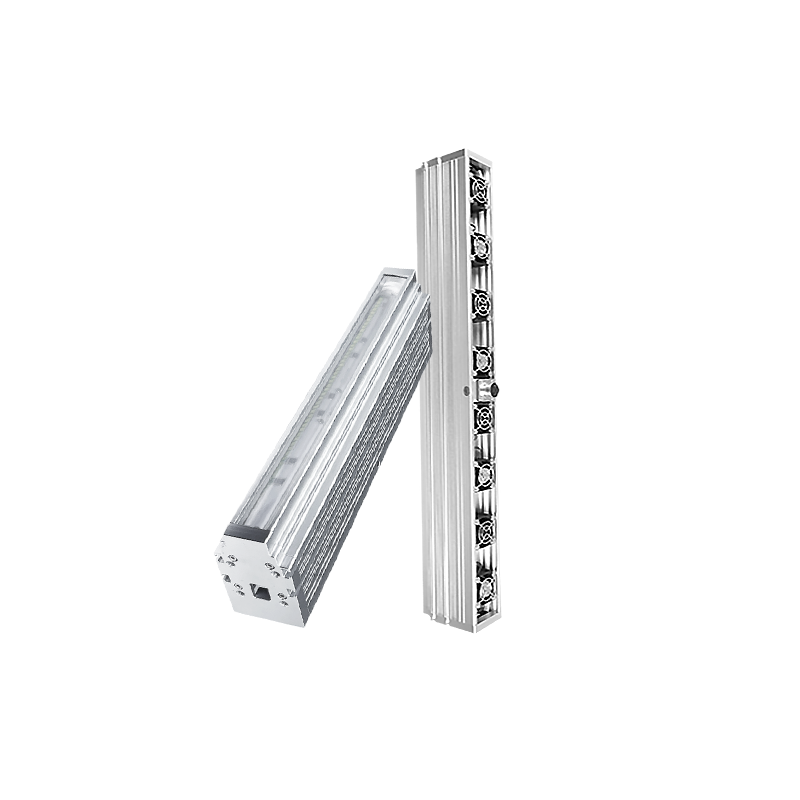

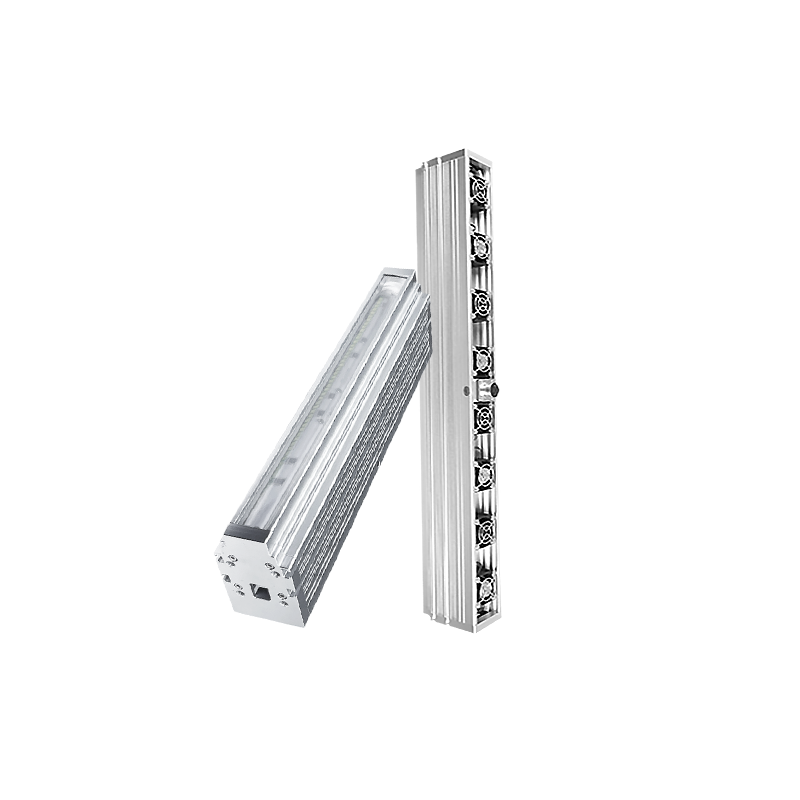

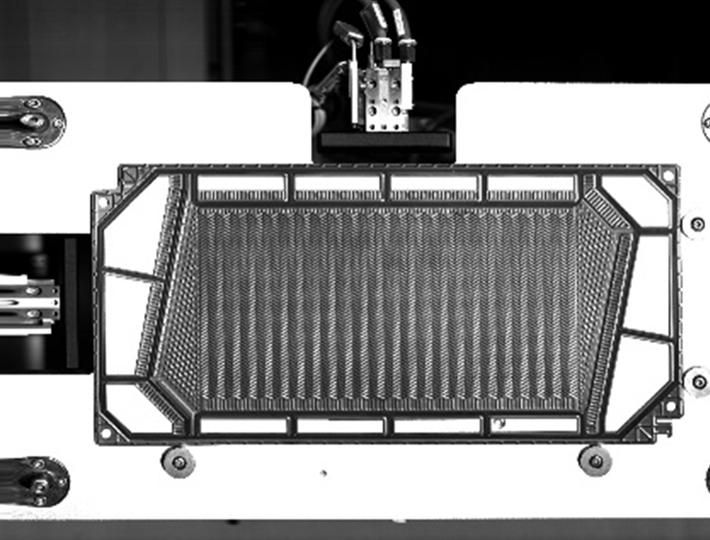

KM-3LI240022 Line Scan Light 3.0 High Brightness

|

HIFLY LED line scan light source can be used for metal surface defect detection,high-speed object real-time capture and printing and packaging detection. |

|

● Power supply: Input 24V DC, power 640-992W. Stable and flicker-free. |

|

● Effective luminous area: 2400 * 22 mm. Customized design is also supported. |

|

● Energy-saving, Super Low Power Consuming, Highly Bright. |

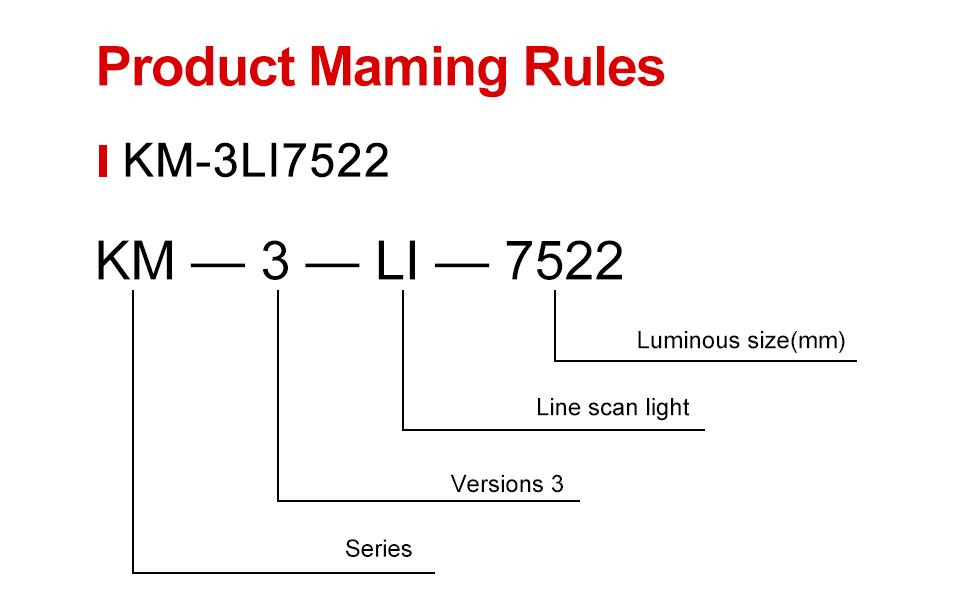

| Model | Luminous size(mm) | Voltage(v) | Power(w) | Plug specification | Weight(kg) |

| KM-3LI7522 | 75*22 | 24 | B/W:31 R:20 | 4-core WS16 specification | 0.6 |

| KM-3LI15022 | 150*22 | 24 | B/W:62 R:40 | 4-core WS16 specification | 1 |

| KM-3LI22522 | 225*22 | 24 | B/W:93 R:60 | 4-core WS16 specification | 1.4 |

| KM-3LI30022 | 300*22 | 24 | B/W:124 R:80 | 4-core WS16 specification | 1.8 |

| KM-3LI37522 | 375*22 | 24 | B/W:155 R:100 | 4-core WS16 specification | 2.3 |

| KM-3LI45022 | 450*22 | 24 | B/W:186 R:120 | 4-core WS16 specification | 2.7 |

| KM-3LI52522 | 525*22 | 24 | B/W:217 R:140 | 4-core WS16 specification | 3.1 |

| KM-3LI120022 | 1200*22 | 48 | B/W:496 R:320 | 6-core WS20 specification | 6.9 |

| KM-3LI135022 | 1350*22 | 48 | B/W:558 R:360 | 6-core WS20 specification | 7.3 |

| KM-3LI150022 | 1500*22 | 48 | B/W:620 R:400 | 6-core WS20 specification | 7.7 |

| KM-3LI195022 | 1950*22 | 48 | B/W:806 R:520 | 6-core WS20 specification | 9 |

| KM-3LI210022 | 2100*22 | 48 | B/W:868 R:560 | 6-core WS20 specification | 9.4 |

| KM-3LI225022 | 2250*22 | 48 | B/W:930 R:600 | 6-core WS20 specification | 9.8 |

| KM-3LI240022 | 2400*22 | 48 | B/W:992 R:640 | 6-core WS20 specification | 10.2 |

| Please contact us learn more models! | |||||

| Model | KM-3LI240022 | ||

| Product Type | Line scan light | ||

| LED Type | SMD | SMD | SMD |

| Colors | red | white | blue |

| Wavelength | 620-635nm | - | 465-470nm |

| Temperature | - | 6000-7000K | - |

| Power | 640W max. | 992W max. | 992W max. |

| Brightness | 450000 LUX | 1500000 LUX | 33000LUX |

| Input Voltage | LED:DC 48V max FAN:DC 24V | ||

| Matching light line | 3 m WS20 six-core light source cable | ||

| Connector Type | WS20 six-pin aviation head socket | ||

| Connector Definition | 1,3: LED (+) red; 2,4: LED(-) black; 5: FAN(+) blue; 6: FAN(-) green; | ||

| Definition | - | ||

| Shell Material | Aluminum alloy (surface color oxidation treatment) | ||

| Cooling Method | Air cooling | ||

| Overall Dimensions | L2420mmxW54mmxH102.5mm | ||

| Weight | 10.2Kg | ||

| Shell Hardness Parameters | Static load 230N±10N, time 5 minutes Contact area: diameter 30MM Energy grade: 5J Element: Steel ball diameter 50MM, 500g±25g |

||

| Insulation Capacity Requirements | DC500V insulation resistance > 20 megohm | ||

| Pressure Requirements | AC1000V 10mA/5S | ||

| Flammability Grade | IEC60707 | ||

| Operating Temperature And Humidity | Temperature: 0 to 50ºC, Humidity: 20 to 85%RH(non-condensing) | ||

| Service Life | Under the conditions specified by the company, red light is 50,000 hours, white light is 30,000 hours, and the brightness is reduced to 50% of the factory value | ||

| Warranty Period | Under the conditions of use specified by the company, the warranty is one year from the date of shipment, and if there is a fault within one year, it can be repaired or replaced for free | ||

| Value-added Services | One year free technical support, free loan sample testing | ||

| Power Supply (optional) | Digital controller | ||

| Supporting Cables (optional) | 3 m /5 m WS20 six-core light source cable | ||

Automotive battery membrane electrode defect detection

The defects such as scratches, drops of glue, dirt and bad adhesive strips are detected in the production process of the membrane electrode of the battery module.

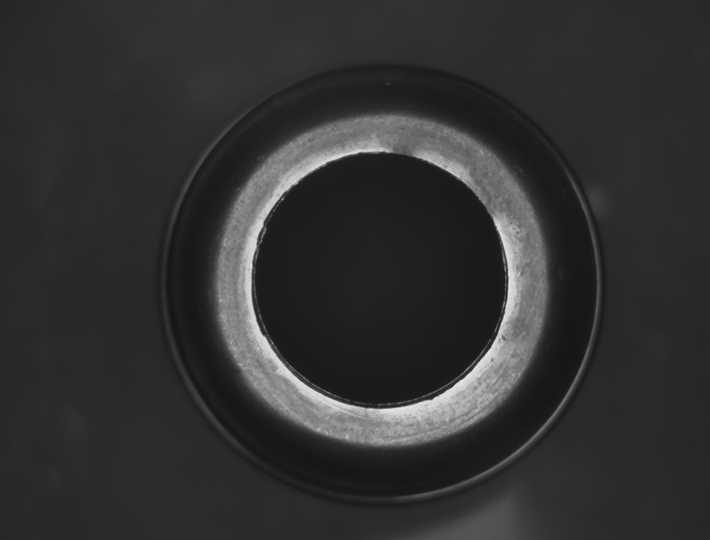

Automobile shaft defect detection

Detect the scratches, rust, dirt and other defects of the automobile shaft in the production process. Improve production efficiency and reduce consumables.

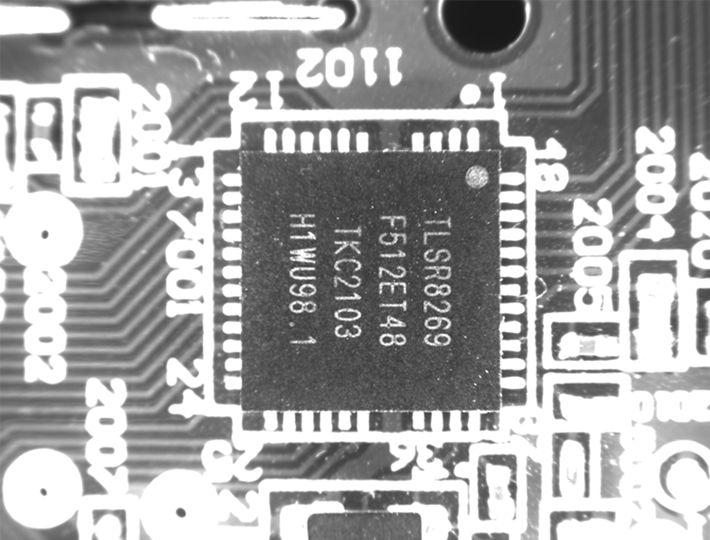

Component print character detection

Detect the defects of electronic components in the production process, such as less printing, missing printing or unclear printing.The line scan light blackens the background and enhances the contrast of white characters.

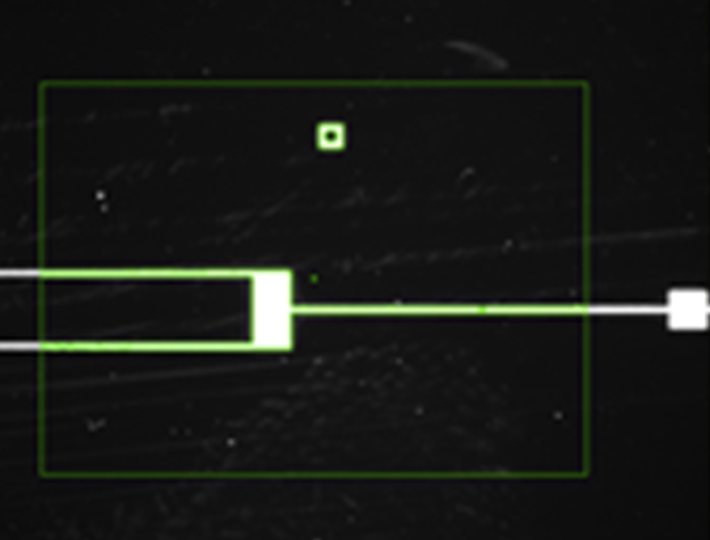

Photovoltaic screen printing detection

Mark point is used to locate the printing position, detect such defects as damage and dirt of the cell plate, and recheck whether the edge of the cell plate is broken or broken after printing.

Q1. Can I have a sample order for 3.0 High Brightness Line Scan Light?

A: Yes, sample orders and any orders are acceptable.

Q2. What is the lead time?

A: 3-5 days for sample/small(<50pcs) orders, 1-2 weeks for bulk buying (>50pcs).

Q3. What's your MOQ for the 3.0 High Brightness Line Scan Light?

A: The MOQ is 1pcs.

Q4. What's your shipment term and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 5-7 days by air. Shipping by sea is also acceptable.

Q5. How to place an order for 3.0 High Brightness Line Scan Light?

A: 1. Confirm parameters such as FOV and WD;

2. Confirm the shape, state, material and color of the detected object;

3. Confirm the order and quote;

4. Pay orders and arrange production;

5. Check the product and arrange delivery.

Q6. Do you support private labels?

A: Yes, we do.

Q7: How long is your product warranty?

A: We offer 2-5 years warranty for our products.

Q8: How do you deal with the faulty products?

A: 1, Our products are produced in strict quality control system with a 0.2% defective rate.

2, If non-artificial damage, dysfunction or errors happen during the warranty period, customers can go for repair, replacement or partial/full refund.

3LI240022(Specifications).pdf

download